If you are an interior architect, you might have dismissed the niche laboratory design market as overly technical and inherently less interesting than working on projects of similar magnitude in the fields of residential or office design.

You Think Laboratory Design is Too Boring? Too Technical? Too Dull?

You might want to think twice before making these kinds of assertions about today’s laboratory design projects.

Stunning designs like the new JLABS facility at the Texas Medical Center in Houston will challenge any stereotypes you may still hold that laboratory design projects are inherently uninteresting, dull or boring.

San Francisco-based architectural giant Gensler partnered with the Houston-based PhiloWilke Partnership to design the new Johnson & Johnson Innovation (JLABS) life science incubator at the Texas Medical Center. Gensler was responsible for the interior design, while PhiloWilke designed the laboratory spaces.

The JLABS project is not just a one-off example. The world of laboratory design is really reaching new heights. To illustrate the point, we turn to R&D Magazine and their annual laboratory design awards.

The R&D Magazine 2016 Lab of the Year award went to the Electrical & Computer Engineering (ECE) facility at the University of Illinois’ Urbana-Champaign campus. Designed by Omaha-based national firm Smithgroup JJR, the ECE has outstanding energy savings characteristics and expects to achieve a Net Zero Energy rating as well as LEED Platinum certification from the U.S. Green Building Council.

Not all lab design projects are new construction; renovations are common in this market sector. An excellent example is R&D Magazine’s recipient for Renovated Laboratory of the Year: a major lab project at Cornell University, designed by the Boston-based architecture firm Payette.

Rounding out this year’s R&D Magazine awards is their Special Recognition for Design, which went to a new patient facility at MD Anderson Cancer Center in Houston, designed by Omaha-based HDR, an architecture and engineering firm with over 10,000 employees worldwide.

The Laboratory Science Market is Good Business for Architectural Firms

While there are relatively few firms nationwide that offer laboratory design services, those that do are part of a multi-million dollar market. As an example, Clark Nexsen, a national architectural firm with locations that include Austin, Raleigh and Richmond, VA, announced that they reached a milestone of projects totaling more than 20 million square feet of work in the broader scientific and technology market space (including tech education facilities).

Other architecture design firms that are punching above their weight in the laboratory science field include:

- The Cooper Carry’s Science + Technology studio (offices in Atlanta, Wash. DC and New York City) which designed the Emory University Atwood Chemistry Building and Addition in Atlanta.

- CRB, the global consulting, design and construction services firm, which designed the Andover Clinical Manufacturing Facility for the pharmaceutical giant Pfizer.

- Houston-based EnergyArchitecture, which has designed laboratory testing facilities around the world for the energy market.

- Svigals + Partners Architects, based in New Haven Connecticut, designers of the new Yale University Integrated Science Technology Center.

What’s Stopping You from Taking a Dive into Laboratory Design?

Have these examples whetted your appetite for pursuing laboratory design projects?

Perhaps you’re interested, but concerned that it’s a step too far into the unknown.

Now might be a good time to quantify what’s similar and what’s different about the discipline of laboratory design compared to other fields of architectural practice.

Fortunately for those making a transition into laboratory design, quite a few key project management and design programming skills needed for major projects are the same, whether the end product is a bank, a holiday resort, an apartment complex, a renovated mix-use historical train station, or a new research laboratory facility.

Project Success Characteristics Shared between Laboratory and Other Projects

- Understanding the needs of the client

- Developing effective project programming

- Ability to manage major clients in the corporate, education, government or military arena

- Partnering with engineering and construction firms

- Managing and delivering major projects on time and on budget

- Developing sustainable designs (e.g. LEED certification, energy reduction)

- Sourcing reliable vendors for specialty applications (such as contract furniture manufacturers, like Formaspace)

How is Laboratory Design Different?

Now let’s take a moment to consider how laboratory design is different from other fields of architectural practice.

At the 10,000 foot level, what’s the main difference?

Regulatory governance is a good answer to that question. There are simply many more things that are regulated in laboratory design — rules and guidelines that are in addition to ‘normal’ regulatory design concerns, such as ensuring safe structural integrity, fire suppression, emergency egress, and the like.

Depending on the specifics, there might, in fact, be one or more regulatory regimes that apply to any particular lab project, so it’s crucial to be able to quickly determine which set of regulations apply when pursuing a lab design project bid opportunity. Having a clear understanding of the regulations will also make it easier to select suitable consultants and experienced vendors and construction contractors for the project.

Requirements governing research laboratories can vary quite a bit as well, depending on their intended use. Some are much more stringent than others. For example, high school or college level teaching laboratories will generally face fewer regulatory hurdles than laboratories designed to handle potentially dangerous materials or compounds.

Pharmaceutical or food manufacturing testing laboratories will need to adhere to the FDA’s current manufacturing process (cGMP) regulations, which will strongly influence the selection of materials, surfaces, and more.

Many sensitive scientific lab experiments or industrial processes (such as growing crystal substrates for mircroelectronic chip manufacturing) have very specific requirements limiting the amount of air-borne particulates that can be present. Laboratories with these requirements will need to be built with specialized airflow and filtration systems in accordance with applicable ‘cleanroom’ standards.

At the far end of the spectrum, the CDC carefully regulates biomedical research laboratories that handle highly dangerous compounds or organisms. These are classified by the CDC into four Bio-Safety levels, 1 through 4. The highest level, Bio-Safety Level 4 (BSL-4), is a designation reserved for laboratories designed to contain the most dangerous agents of all, such as anthrax bacteria or Ebola virus. Naturally, BSL-4 labs require the most stringent planning and engineering oversight for design approval and operation.

The Language of Laboratory Design

There are other terms that are unique to laboratory science that everybody needs to learn in order to better understand this market niche.

Traditionally, laboratories were broken down into two broad categories: Wet Labs and Dry Labs (Tech Labs).

Wet Labs

A Wet Lab is the traditional term for any laboratory that uses liquid chemicals. Here, the designer needs to know how to specify the right chemical resistant surfaces (to match the chemicals or compounds used in the lab), built-in wet sinks (with drainage lines sometimes running to a filtration system rather than the primary sewer stack), and fume hoods (to protect lab workers from inhaling gases or particulates.)

Dry Labs (or Tech Labs)

A Dry Lab, as the name implies, is a designation for laboratories that use small amounts of dry chemicals, if any. In fact, as computers and other testing equipment have become primary tools for scientific investigators, many Dry Labs today are referred to simply as Computer or Tech Labs. As such, they may have additional design considerations, such as the need to isolate highly-sensitive test equipment from sources of vibration or the need to keep computer equipment and networks cool and powered up – with dedicated HVAC systems and emergency power backup systems.

Other considerations: Cleanroom and Electronic Discharge Protection Systems

There are additional design requirements which can apply to Wet, Dry, or Tech Labs. Here are two examples:

The first one (mentioned above) is the potential need for a cleanroom system, designed to prevent sensitive equipment from exposure to micro-particulates. Cleanrooms typically require complex HVAC and filtration systems.

The second is the need to protect sensitive electronic equipment from potential damage due to inadvertent electric shock, which can be caused by simply touching a component with your hands or tools. In these cases, the laboratory will need to be protected with built-in anti-static protections.

Isn’t it Time to Look at Opportunities in Laboratory Design?

We realize the information provided here just scratches the surface, but hopefully, it piques your interest to learn more about the business of laboratory design.

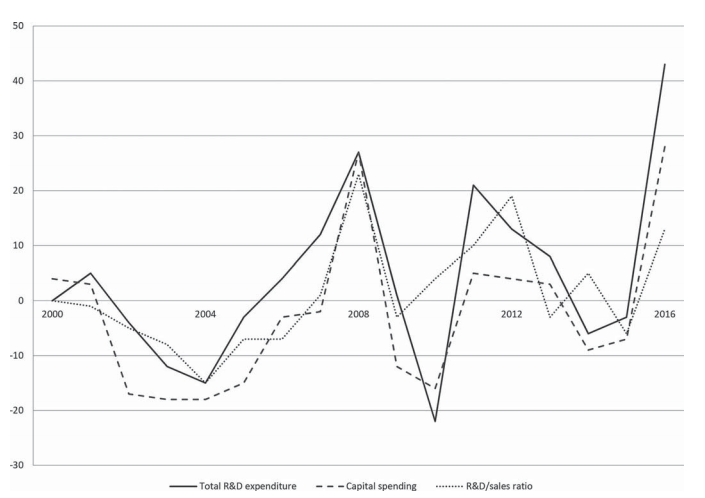

After all, it’s a big market. According to the Industrial Research Institute’s Annual R&D Trends Survey, total U.S. R&D spending was expected to grow to $507 billion dollars for 2016. Of that total, survey participants indicated they planned to allocate around 18% of their budgets (circa $91 billion dollars) toward capital expenditures, including investments in research laboratory design, construction and renovation projects as well as the acquisition of new specialized test equipment.

How to Learn More about Laboratory Design

Want to learn more about laboratory design?

Why not join your fellow architects at the next national Lab Design Conference, which will be held this coming April 24-26, 2017 in Raleigh, North Carolina?

Formaspace will be there exhibiting our line of laboratory furniture at the show and you can meet Formaspace CEO Jeff Turk, who will be giving a stage presentation to the conference on lab design spatial efficiency.

Formaspace is also a great resource for architects to turn to when you have questions about laboratory design. Our Design Consultants are standing by to answer any questions you have. We can also provide full-service assistance in designing your next laboratory project – even if it’s your first one.

We have built furniture systems for hundreds of laboratories nationwide; our client’s list includes Abbot Laboratories, Amgen, Baxter, Bayer, GlaxoSmithKline, Johnson&Johnson, Merck & Co., Novartis, Pfizer, Roche, Avero and Quest Diagnostics Inc.

Will your project be next? We hope so. Contact your Formaspace Design Consultant today.