Ensuring a water supply is clean and safe requires the efforts of government agencies and the private sector supported by water testing labs that detect, evaluate, and report findings. Today, even with new technology and methodologies stimulating remarkable advances in the field, water testing laboratory technicians must remain vigilant in testing for and analyzing up to 90 different contaminants currently designated by the U.S. Environmental Protection Agency (EPA) as potentially affecting drinking water.

Circumventing this process can lead to catastrophic results.

In April, after four years of disastrous actions (and inactions), residents of Flint, Michigan officially heard that their drinking water was finally safe. The announcement from Governor Rick Snyder appears to conclude a public water safety emergency that has impacted nearly 100,000 Flint city residents since 2014.

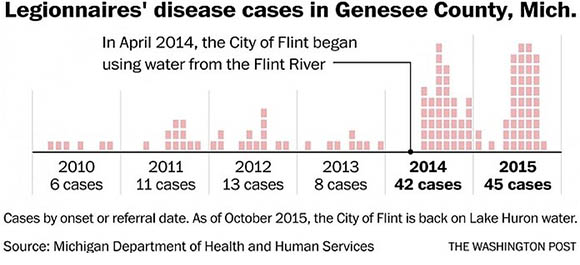

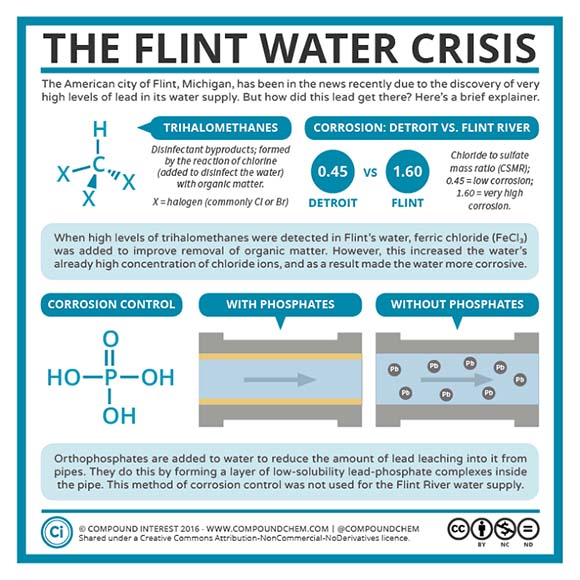

The tragedy in Flint began when residents objected to the foul looking, smelling, and tasting water coming through water pipelines. The local government, seeking cost-savings, choose a different source for the public water supply. Parents soon noticed that their children suffered from skin blotches, hair loss, sleep issues, and memory loss. An estimated 6,000 to 12,000 children were exposed to what was soon determined to be high levels of lead in their drinking water. The Flint Water Crisis, as it became known nationally, also included a Legionnaires’ disease outbreak that resulted in the deaths of 12 people.

Further, when E. coli was suspected in Flint River water, ill-fated attempts to combat it resulted in more corrosive and an even higher concentration of lead in the water.

An array of corrective actions and a $450 million aid package was necessary to finally resolve the dangerous public water safety issue. Even then, residents were dependent on government-supplied, bottled drinking water and water filters for more than two years. During the course of this journey, more than a dozen lawsuits and several class-action suits were filed. Four government officials resigned over the mishandling of issue, and more than 15 criminal cases were filed against local and state officials.

Crisis Illustrates Importance of Water Testing Labs

But good can come out of adversity. In Flint, engaged residents working with water testing laboratory specialists initiated actions that would eventually resolve the water safety issues. Flint resident and mother of four, LeeAnn Walters, received the Goldman Environmental Prize for her efforts in the grassroots environmental activism. She had reached out to Professor Marc Edwards who established Virginia Tech’s Flint Water Study Team that first uncovered the high concentration of lead in Flint’s public water supply. Edwards was recently awarded a three-year and nearly $2 million grant from the EPA to detect and control lead levels in public drinking water.

The Flint Water Crisis helped generate interest among the public in water treatment best practices and helped showcase the vital role that water testing laboratories play in ensuring public safety. Since it became national news, the public has shown an increased awareness of water quality issues. Results from a public survey conducted on behalf of the Water Quality Association in early 2017 show that the public is now more than twice as likely to recognize lead as a water contaminant compared to just two years earlier (15% in 2015 versus 33% in 2017) and is more concerned about contaminants of all kinds in tap water (25% in 2015 versus 36% in 2017). (The full WQA survey results can be found here.)

Public concern about water pollution and contamination is warranted.

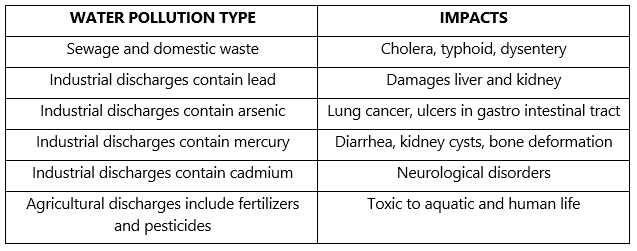

The impact of polluted water from sewage and domestic wastes, plus industrial and agricultural discharges can result in serious health issues, including diseases and harm to vital organs of the body. An estimated seven million people in the United States alone get sick from drinking polluted water every year.

The presence of certain contaminants in our water can lead to health issues, including gastrointestinal illness, reproductive problems, and neurological disorders. Infants, young children, pregnant women, the elderly, and immunocompromised persons may be especially at risk of becoming ill after drinking contaminated water.

Water Testing Lab Market Projected to Grow at CAGR of 5.2% by 2019

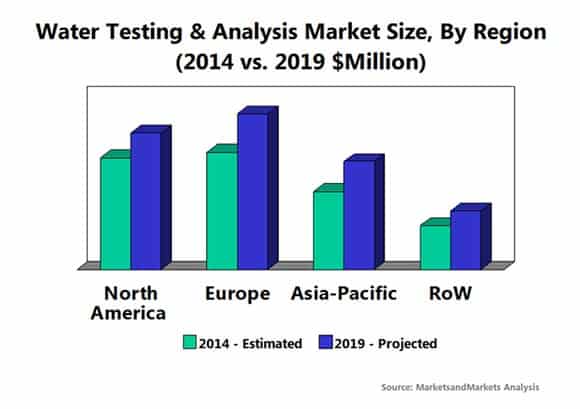

Water testing labs play a vital part in ensuring safety for public drinking water supplies as well as water utilized in business and industry. The demand worldwide for water testing and analysis instruments in all settings — laboratory, industrial, environmental, government, and other applications — is projected to grow at a CAGR of 5.2% and to reach a value of $3.5 billion by 2019.

This means existing water testing laboratories should be prepared to take on additional project work when the need arises. New water testing labs should plan for their lab design to accommodate future growth opportunities.

EPA Standards Ensure Public Safety

Because the EPA monitors more than 90 contaminants in drinking water and oversees the water testing schedules and methods that public water systems must follow, it has established strict water testing laboratory certification requirements.

Approved water testing labs must:

- Be certified by EPA or the state to analyze drinking water samples for compliance monitoring

- Successfully analyze proficiency testing (PT) samples at least annually for each method and analyte for which they desire certification

- Use approved methods

- Pass periodic on-site audits

Lab managers also need to be aware that individual states are enabled, through the Safe Drinking Water Act, to set and enforce their own drinking water standards as long as they met the minimum national standards established by the EPA.

Good Water Quality Vital for Business and Industry

Beyond the importance of safe drinking water for individual consumption, clean water also plays a vital role in manufacturing facilities. The quality of water used impacts the grade of the final products, so testing water quality is an essential part of many industrial operations.

Local industry was also negatively impacted by the poor water coming through public pipelines from the Flint River. General Motors, for example, soon realized the tainted water from the river was rusting engine blocks and causing visible corrosion damage on parts coming out of its machining process. The problem was not lead but the elevated levels of chloride in the compromised river water. For months, factory officials tried workarounds, such as reverse osmosis as a purification process and trucked in additional water to dilute chloride levels. These unsuccessful efforts proved time-consuming and costly. Finally, at a considerable additional expense, the company determined it needed to purchase clean water through another channel and by direct connection to a Lake Huron water supply pipeline.

Even in typical and ideal situations, businesses realize the importance of clean water to their operations. Unsafe water-wasting production methods jeopardize long-range production costs. More than 90% of businesses in water-intensive industries and over 60% of business in non- water-intensive industries have developed a formal water strategy to preserve this vital resource.

Lab Testing is a Multi-Step Process

Water testing laboratories play a key role in these efforts by ensuring a clean and safe water supply. The process utilized often involves many facets.

Testing may be performed to evaluate:

-

Environmental water quality

Following the passage of the Safe Drinking Water Act by Congress in 1974, the EPA was designated as the authority for setting and administering quality water standards utilized by states, localities, and water suppliers for water supplies for public water sources that include rivers, lakes, reservoirs, springs, and groundwater wells overseas.

-

Wastewater

The EPA defines this as the water carrying wastes from homes, businesses, and industries that is a mixture of water and dissolved or suspended solids.

-

Raw water

This is water in its natural state, prior to any treatment for drinking, as defined by the EPA.

-

Finished water

Water is “finished” when it has passed through all the processes in a water treatment plant and is ready to be delivered to consumers.

-

Water for industrial use

This includes laboratory, manufacturing, or various industrial settings (including in mines, factories, and chemical processing plants or similar sites).

While the evaluation categories for water testing laboratories have remained generally unchanged, the criteria are constantly being evaluated and amended by governing agencies.

Design Elements for Water Testing Lab

Staying up-to-date with water testing laboratory regulations also requires ensuring you understand what furnishings and equipment are best suited for your laboratory.

Formaspace has experience in developing laboratory solutions for organizations of all sizes, including Fortune 500 companies. Contact the Formaspace team of Design Engineers and Design Consultants today to learn how a solution can be tailored to your unique needs.

Design elements in your water testing laboratory can include:

-

Instrumentation and sample processing lab tables (integrated with testing equipment)

Water testing laboratory technologies and instrumentation advance rapidly. Providing an efficient laboratory design, durable furniture, and enabling mobility of sample processing equipment increase operational efficiency.

-

Custom workbenches with integrated waste cut-outs

Efficient waste disposal options can be incorporated into water testing laboratory workbenches ensuring lab personnel safety. Cut-out compartments or disposal containers mounted under or above the work surface will accommodate your lab requirements.

Lab architects find modular lab furniture offers a cost-effective means to incorporate new technology, accommodate customization, and reconfiguration lab components as project scopes expand.

-

Safety cabinets

Researchers can safely work with materials contaminated with pathogens under a biosafety cabinet provided by Formaspace.

-

Fume Hoods

Clearing the air of chemical fumes and toxic gases can be accomplished effectively with fume hoods built for quality and longevity. Formaspace offers air-clearing solutions for every lab application.

-

Chemical resistant countertops

Formaspace offers a variety of Workbench Surfaces for every workbench application from Chemical Resistance to ESD Protection. If you need assistance deciding between the laboratory countertop options, please review “Which Chemical Resistant Countertop is Good for Your Lab Project?”

Whether your countertop laboratory requires moderate, light duty, or high chemical resistance, Formaspace can accommodate your needs.

-

Mobile lab carts

Rack units help eliminate labeling errors. Each mobile warehouse rack provides sealed storage with ten individual locking shelves that ensure “chain of custody” in each compartment.

-

Epoxy lab Drying Rack/ Pegboard

Laboratory peg boards provide a location to dry glassware and other vessels used in your laboratory. Choose from stainless steel, epoxy, phenolic, laminate, or HDPE for your wall mounted lab drying rack.

-

Laboratory accessories

Formaspace offers many accessories lab sinks and special lighting to complete your lab design. Including:

-

Lab sink

Two-hole single bowl top-mount sink in stainless steel that is crafted with uncompromising attention to detail to ensure a lifetime of function and beauty.

-

Workbench Light / Overhead Light

An overhead light assembly that mounts to the bench providing optimal lighting and working conditions.

-

Under Shelf Light

Shelf light assembly that mounts under shelves on the bench to provide lighting to work surface.

-

Magnifying Lamp / Lighted Desk Magnifying Lamp

Heavy duty magnifying lamp that uses a spring balanced tension bars to adjust to numerous positions and can also be locked into place at its joints.

You can learn more about water quality and safety in your area, by visiting the EPA website.

You can learn how the quality of water in your area compares to state and national averages and health guidelines through the Environmental Working Group’s Tap Water Database.

Turn to Formaspace for Custom Design Element Solutions for Your Water Testing Labs

Formaspace presents unique products that meet all your laboratory requirements and can provide you with proper furniture installation.

Want to learn more?

If you are starting your own water testing lab or seeking to refurbish your existing laboratory, contact Formaspace today, they can provide you with all your lab design and furniture needs. We have experience based on thousands of installations and would be pleased to answer any questions you might have about our products or provide design service assistance.