Custom-designed Drug Storage Solution helps prevent medical errors while reducing warehouse space requirements by more than 90%.

Austin, TX (Aug 22, 2016) According to the research report “Preventing Medication Errors” published by the Institute of Medicine of the National Academies, the number of preventable adverse drug events (ADEs) in this country now totals approximately 1.5 million incidents annually. In response, healthcare providers across the continuum of care are working together to reduce this number of preventable ADE cases.

For pharmaceutical manufacturers and pharmacies who distribute millions of prescription medication dosages each year, it’s critical to eliminate the possibility of errors in product labeling will occur.

When one of the largest pharmaceutical companies in Texas wanted to upgrade their material handling, bag fabrication, and filling process to make it more efficient and less prone to labeling errors—they called on Formaspace.

We were able to evaluate the pharmaceutical company’s operations and identify a bottleneck in their cleanroom operations.

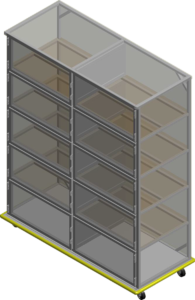

According to Bill Lambert, Formaspace Director of Operations, “Upon making a thorough assessment of our client’s manufacturing process, we were able to design a new, custom mobile racking system that provides a more secure, positive ‘chain of custody’ for their prescription drug products. We also leveraged this new design to create a matching warehouse racking system that uses 90% less storage space – providing significant annual savings.”

The new mobile racking system, designed and built by Formaspace, facilitates the easy transfer of the manufactured pharmaceutical products from the bag fabrication area to the filling areas.

The new rack units also work to eliminate labeling errors. Clear polycarbonate doors keep the product shelves sealed during cleanroom operations. They also allow for product inspection and line clearing without having to open the doors. Each mobile warehouse rack provides sealed storage with ten individual locking shelves. Additionally, each door compartment incorporates a unique lock so only the authorized personnel entrusted with the ‘chain of custody’ for each specific product can gain access to a particular compartment. This important safety feature provides an additional quality control check to prevent accidental misloading of incorrect pharmaceutical products.

The frames of the racking systems, which operate in clean rooms, are made of stainless steel. Color-coordinated bumpers provide an important visual cue for plant operators to locate and store the mobile units in their correct location when not in use. The frames for the warehouse racking system are made of powder-coated steel.

“Our pharmaceutical client assures us they are on track to save $1 million dollars each year on labor costs by using the new, efficient mobile racking system we’ve designed and manufactured for them,” says Jeff Turk, President, and CEO of Formaspace. “We’re incredibly proud to help companies with new, innovative solutions for their manufacturing processes. As a company, our mission is to provide a complete solution for our clients — from providing lean manufacturing consulting services all the way to designing and manufacturing unique industrial furniture here at our Austin, Texas factory. We’re not satisfied until our clients tell us that Formaspace has helped them become significantly more innovative and productive in their chosen line of work.”

About Formaspace

When Innovation Matters℠

Formaspace provides “Rapid Plant Assessment” consulting services to help manufacturers work leaner, faster, and smarter.

Formaspace also advances the spirit of discovery and creation through the design and manufacture of elegant, practical, and flexible furniture solutions for customers in the laboratory, office, and industrial environments.

As a proud American furniture manufacturer, Formaspace guarantees all products for a full 12 years — the best warranty in the industry.

Formaspace serves over 80% of the Fortune 500. Our extensive client list includes famous names like Apple, Boeing, Capital One, Dell Computer, Ford, Google, Medtronic, and Toyota, as well as leading universities and educational institutions, major healthcare facilities and research laboratories, military and government agencies, small businesses and individuals.