At NeoCon 2024, Formaspace is presenting the Future of Lab.

To better understand the laboratory of the future, let’s take a retrospective look at the evolution of laboratory science.

Pre-18th Century

18th and 19th Century

American and European Laboratory Design Before World War One

American ingenuity in the 19th and early 20th Centuries brought us revolutionary advances in communication (the telegraph network, telephone, phonograph, motion pictures), transportation (the intercontinental railway, first airplane, affordable automobiles), and electric appliances (the incandescent light bulb, vacuum cleaner) just to name a few.

The famous American laboratories of the period were typically privately funded and often located in rustic buildings or converted garages or horse stables. Most were typically constructed of wood or brick, with exposed brick or wood beadboard wall surfaces, large wooden sash windows, and rough-sawn floorboards equipped with basic free-standing wood furniture.

Interestingly, many of the seminal experiments of the period relied on what we might today call a “makerspace” type laboratory; lab scientists regularly used machine tools to craft unique custom equipment for their experiments, for example, using glassblowing techniques to create individual vacuum vessels.

In contrast to American laboratories, the best-known European labs in the period were established by major universities or state-sponsored institutes.

An example is the Cavendish Laboratory at Cambridge University in the UK, where in 1917, New Zealander Ernest Rutherford was the first to split the atom and identify the neutron. Despite its prominent role in physics discoveries, the Cavendish Lab remained a hodge-podge of cramped lab quarters and building additions typical of urban Victorian architecture in Britain.

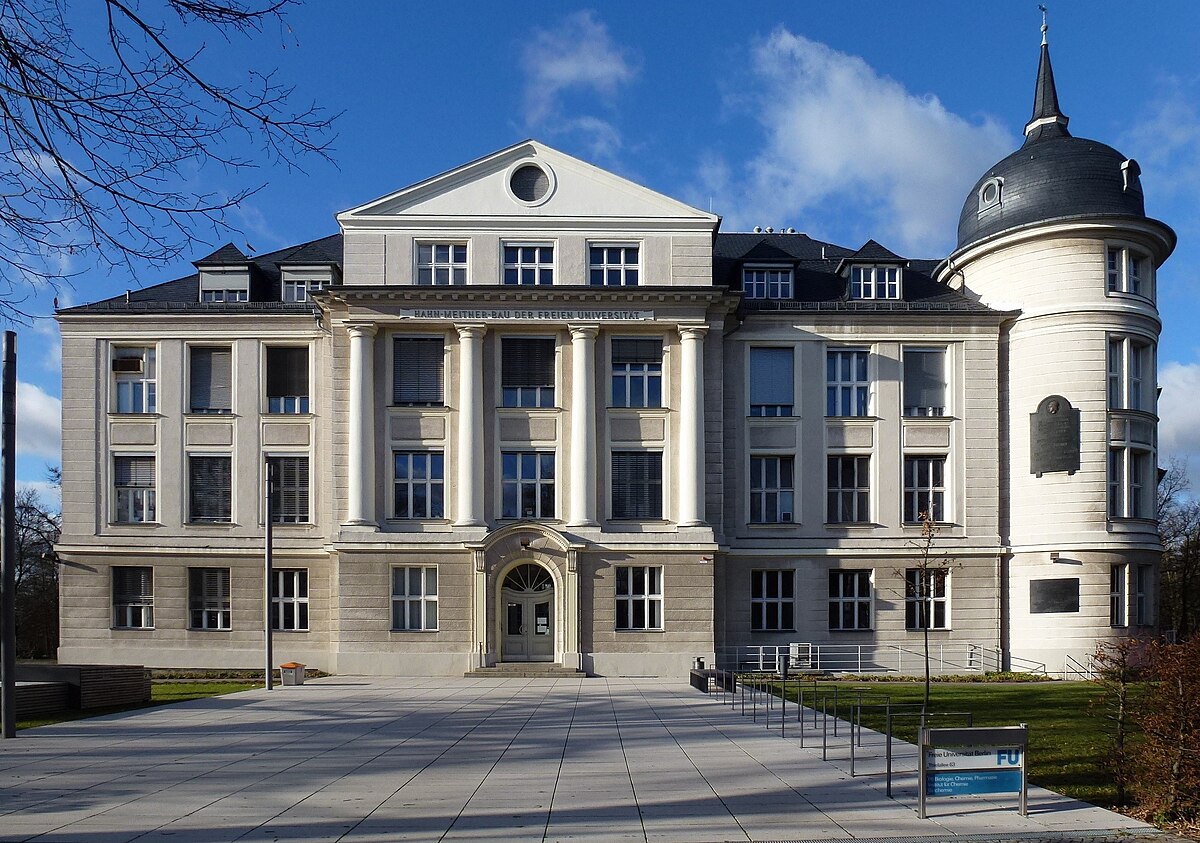

In contrast, Germany constructed numerous modern, purpose-built scientific research institutions, including The Prussian Academy of Sciences and Humboldt University in Berlin. The goal was to advance the field of German science, to train young scientists, and to recruit the world’s best talent, including Albert Einstein, whom physicist Max Planck personally recruited in 1914 from Switzerland to join the Kaiser Wilhelm Gesellschaft (KWG) institute (shown above) in Dahlem, a wealthy, leafy enclave of Berlin.

Some German laboratories were built according to the Kirkbride Plan (a 19th-century American innovation in hospital and mental asylum design) that incorporated long, narrow ‘batwing’ corridors spreading out from the center to improve crossflow ventilation and access to natural light.

This focus on ventilation and natural light would become a laboratory design theme once again in the 21st Century.

The German investment in science led to a big economic payoff, particularly in the field of organic chemistry. By the end of the 19th century, Germany was an industrial powerhouse, profiting from innovations introduced by BASF (color dyes), Bayer (phenacetin and later aspirin and heroin), Fardverke Hoxt (analgesics Antipyrene and Amidopyrene, the first synthetically produced drugs), Hooks (novocaine), and Merck (the alkaloids oxycodone and morphine).

Several successful German companies established American operations, including the pharmaceutical manufacturer Merck (1891 in Boston and Rahway, New Jersey) and the chemical producer Rohm and Haas (1917 in Philadelphia). Both companies were nationalized by the US government during World War One, which helped kick-start today’s domestic chemical and pharmaceutical industry hubs in Boston, New Jersey, and Philadelphia.

Early 20th Century

Laboratory Design in the Interwar Period

World War One led to the death of millions and toppled the European Ancien Régime in the process, ushering in today’s modern world. The Spanish Influenza pandemic (1918-1920), which killed over half a million Americans here at home and as many as 60 million worldwide, aggravated the wartime suffering.

The Spanish Flu pandemic also greatly influenced architecture and design after the war, leading to the adoption of a new “Sanitary” design aesthetic. A growing awareness of germ theory spurred a rapid shift away from Victorian design elements (characterized by porous wood paneling, decorative wallpaper, knickknack collectibles, multi-layered fabric curtains, and Persian carpets), all of which were suspected of harboring dreaded influenza germs.

In their place, buildings adopted features such as gleaming white porcelain tiled floors (often with matching white tiled walls), stainless steel worksurfaces, nickel-plated (later chrome) plumbing fixtures, seamless porcelain or stone sinks, bright bare bulb electric lighting, and generous use of white paint to highlight any unwanted dirt and germs.

The new “fresh air” sanitary movement promoted the idea of keeping windows open even during which, which necessitated larger steam boilers in colder climates to compensate for the loss of heat during winters.

Modern laboratory designs from the interwar period adopted these new sanitary features, such as easy-to-clean seamless linoleum floors and built-in wood cabinets (typically painted in a sanitary white), though metal casework cabinets with gleaming white porcelain surfaces and black trim were also common. Worksurfaces were now often constructed of chemical-resistant materials, such as stainless steel, or the ubiquitous fire-resistant black countertops, which in those days were made of asbestos cement (phased out by the early 1980s due to health concerns). Unlike today’s modern open lab layouts, floorplans of the era were typically very compartmentalized, with small individual rooms dedicated to single functions, separated by doors.

Much of American laboratory research focused on innovations in manufacturing (primarily consumer goods), including the mass production of automobiles, airplanes, light bulbs, radio vacuum tubes, shatterproof Pyrex® glass cookware, and early cathode ray tubes. Chemical companies introduced new materials, including silicone, neoprene, advanced polymers, nylon, and Teflon during the interwar years.

German architects and designers were experimenting with modernist designs in the 20th Century, a movement that extended to industrial buildings and factories, notably the 1908 AEG Turbine building in Berlin’s Moabit district, designed by Peter Behrens. Behren’s young architect employees Le Corbusier, Ludwig Mies van der Rohe, and Walter Gropius would later become famous in their own right, with Gropius founding the Bauhaus modernist collective and Mies bringing the “International Style” to Chicago and New York in the post-WWII era.

In contrast, interwar American commercial architectural design in the interwar period was quite modest and conventional, following the traditions of neo-classical architecture or, in some cases, a nod to the prevailing art deco/moderne streamline trends.

One exception was the landmark 1939 Johnson Wax headquarters in Racine, Wisconsin, designed by Frank Lloyd Wright. This revolutionary design was, without question, many decades ahead of its time. It featured breathtakingly delicate high-strength golf-tee-shaped reinforced concrete columns that suspended a skylight ceiling overhead, flooding the revolutionary open office layout below with natural light. It would be nearly half a century before open floor plans such as this became widely adopted.

Laboratory Construction During World War II

The surprise attack on Pearl Harbor by the Japanese on December 7, 1941 (and the declaration of war against the US by Hitler the following day) marks the start of America’s industrial mobilization.

The research and development innovations created by the Allies, which include advanced radar detection and jamming systems, the Norden bomb site, the Proximity fuse, Ship degaussing (to evade magnetic mines), Napalm incendiary bombs, the famous Jeep, Liberty ships, artificial rubber, and jet aircraft propulsion, are too numerous to discuss in detail.

Instead, we will highlight three major laboratory research projects during World War II:

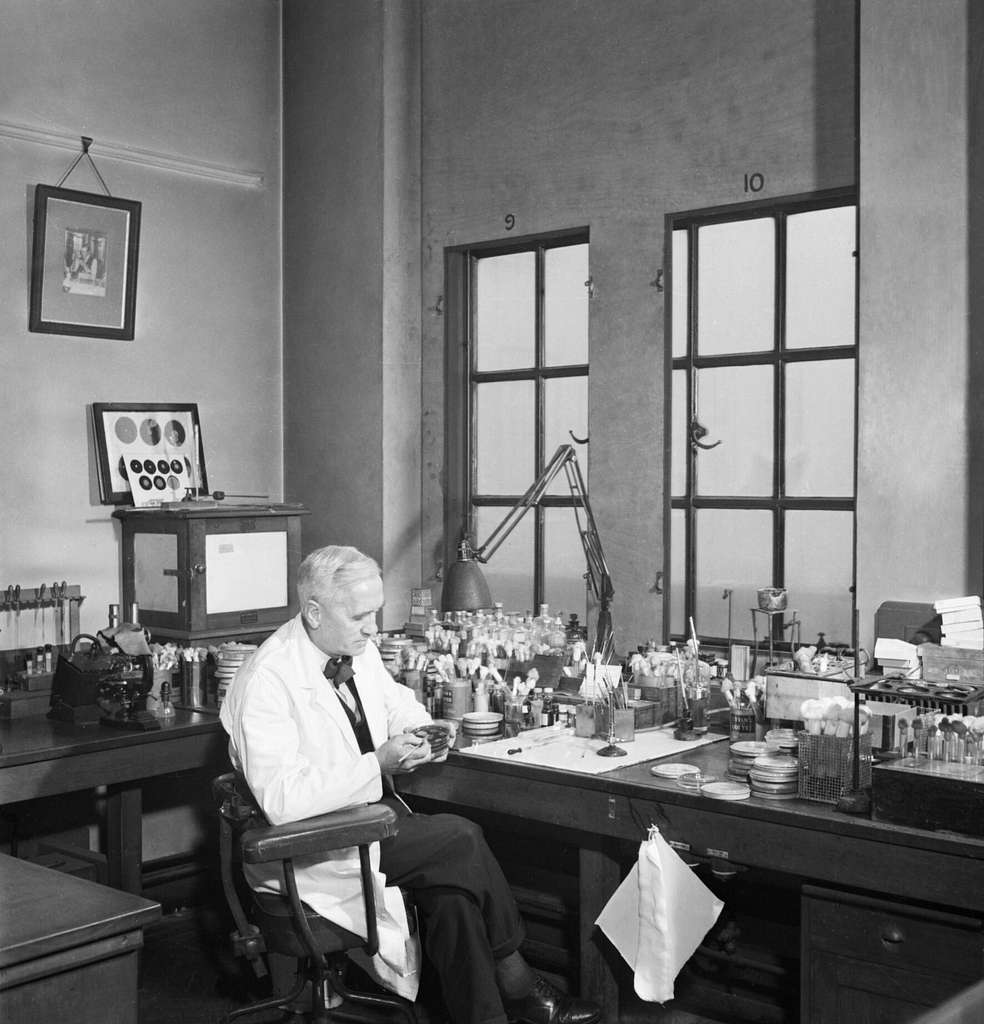

The first was the mass production of penicillin, which saved the lives of countless wounded Allied soldiers whose lives might have been lost to infections such as sepsis. Originally identified in 1928 by Scottish physician Alexander Fleming, penicillin proved difficult to mass produce. During WWII, Oxford University researchers Florey and Heatley came to the USDA research laboratory in Peoria, Illinois, where they developed more effective strains and large-scale fermentation methods to mass produce the life-saving drug. The US War Production Board assigned the manufacturing contract to Merck & Co., and by 1943, over 2.3 million doses were available for the D-Day invasion of Europe. Florey insisted that penicillin not be patented for the benefit of humanity. The subsequent postwar commercialization of penicillin helped pave the way for a whole host of antibiotics introduced in the postwar era.

The second notable WWII development was the secret program to read the encrypted communications of Axis war leaders. This not only decisively helped win the war against the Axis, but it also helped to lay the groundwork for postwar developments in computer science. Dubbed codename Ultra by Churchill, this British intelligence operation was headquartered in Bletchley Park, equidistant from Cambridge and Oxford. This overflowing complex relied heavily on primitive, temporary Quonset huts to house mathematicians and cryptologists working long, exhausting hours decrypting intercepted radio messages sent by the German armed forces (encoded via the famous Enigma machine). It later encrypted teletype messages sent over the airwaves by Hitler’s high command (encoded by the Lorenz machine, called “Tunny” by Bletchley Park). A similar effort by the US Navy operatives in America, dubbed “Purple,” helped decode Japanese military messages, leading to the decisive Pacific theater naval victory at Midway and the eventual fatal in-flight interception of Admiral Isoroku Yamamoto in the Solomon Islands.

While the details of these cryptography programs remained top secret for decades following WWII, the computing innovations, such as Alan Turing’s electromagnetic “Bombe” used to decrypt Enigma messages and Tommy Flower’s Colossus programmable electronic (vacuum tube) computers (used to decrypt Lorenz aka “Tunny” messages) set the stage for postwar developments computer science championed by Alan Turing and his colleague Von Neumann (the father of modern programmable computer architecture) at Princeton University.

The third WWII technological project is one we are now quite familiar with, the Manhattan Project, the code name assigned to the project to develop the nuclear bomb, which was greenlit by FDR after receiving an urgent missive from none other than Albert Einstein who was worried about rumored Nazi nuclear plans. Kickstarting the program was the technology transfer of extensive physics research from the British to the Americans, authorized by Churchill under the code name “Tube Alloys.”

The sprawling top-secret Manhattan Project became the second most expensive initiative of World War II (the most expensive was the Boeing Superfortress program, which deployed atomic bombs over Hiroshima and Nagasaki). The Manhattan Project created a grand, secret network of research facilities, many of which have continued in operation well into the postwar period, including the Enrico Fermi Lab (originally at the University of Chicago), Oak Ridge, Tennessee (uranium ore separation), Hanford Nuclear Reservation (plutonium production overseen by DuPont, now deactivated), the University of Berkeley’s Cyclotron atomic research laboratory (and later Lawrence Livermore Laboratory), and the Los Alamos Laboratory (atomic bomb design and deployment testing laboratory).

Mid-20th Century

Laboratory Design in The Postwar Period

When we think of postwar laboratories, a few design innovations come to mind. The first is fluorescent lighting, which became commercially available in 1938 and found use in many industrial factories during WWII. In 1946, the now ubiquitous “slimline” configuration (a fixture with a pair of 4-foot-long fluorescent tubes) was introduced, and it outsold conventional incandescent bulbs during the 1950s. In lab designs of the period, fluorescent fixtures were often attached directly to asbestos acoustic tiles glued to the ceilings or mounted inside drop ceiling panels fitted with plastic light diffuser screens.

Formica brand laminate was patented way back in 1918, but the introduction of new colors and patterns in the post-war era made it a popular choice for floors and cabinet surfaces (in laboratories, the use of Formica was limited to settings with minimal chemical and heat resistance requirements).

The third change was the widespread introduction of fixed metal-framed glazing, a feature of mid-century modern architecture’s penchant for glass curtain exterior walls. Without large opening windows, laboratories now relied on the introduction of powerful, dedicated air conditioning (HVAC) systems. These were designed in combination with externally vented fume hoods connected to roof-mounted exhaust stacks to maintain fresh, safe conditioned air inside the lab.

Relations with our one-time World War II ally, the Soviet Union, soured during the early postwar period, fomented by what Churchill called a Communist “Iron Curtain” descending over eastern Europe, an emerging spy scandal within the wartime Manhattan Project, and the subsequent Soviet explosion of an atomic bomb (1949) and hydrogen bomb (1955). The ensuing undeclared “Cold War” meant that many government laboratories created during war mobilization weren’t demobilized, and in many cases, government research funding increased. The surprise launch of the Soviet Sputnik satellite in 1957 led to major soul-searching in American science education and the quick reorganization of American civilian and military aerospace research into the new NASA organization in 1958. Funding for science education and research increased further when, in 1961, President Kennedy declared the Space Race to put a man on the moon before the end of the 1960s.

Biological research also got a boost in the early postwar period. The National Research Council funded research at the Mayo Clinic that led to the discovery of the steroidal hormone Cortisol for treating rheumatoid arthritis, earning the researchers a Nobel Prize in 1950.

Preventing the spread of polio remained a top goal of the era. FDR had contracted paralytic polio in the 1920s, rendering him unable to walk without canes or metal braces. In 1948, Boston’s Children’s Hospital researchers successfully cultivated the polio virus in human cells, and in 1952, researchers at the University of Pittsburgh (led by Jonas Salk) created a prototype live virus polio vaccine, which was introduced in 1955. Unfortunately, it was soon discovered that a small percentage of children acquired paralytic polio from the vaccine, reducing public confidence in the program. By 1957, the Swedish researcher Albert Sabin developed a safer oral polio vaccine, which widely supplanted the original Salk formula.

Biology researchers also made major strides in understanding the inner workings of cell replication during the mid-1950s. Teams at King’s College London (Maurice Wilkins and Rosalind Frankly), at Caltech (led by Linus Pauling), and at Cambridge (Crick and Watson) sought to uncover the illusive structure of DNA. Each group made significant contributions, but, in the end, Crick and Watson garnered the spotlight for their ability to describe how the complex helical DNA structures “unwrap” themselves temporarily to duplicate their genomic code.

“Think tank” was a new term that entered the post-war lexicon to describe large research and development organizations dedicated to innovation, from scientific discovery to crafting public policy recommendations. Two new think tanks emerged after World War II: the independent Stanford Research Institute (now SRI International) in 1946, which helped lay the foundation for today’s Silicon Valley, and The RAND Corporation, founded in Santa Monica, which grew to become a key resource for government scientific and military planning. The Battelle Memorial Institute in Columbus, Ohio, founded in 1929, developed R&D expertise in many areas, especially nuclear science, and was awarded a series of management partnership contracts overseeing many of the nuclear government laboratories established during the Manhattan Project.

Perhaps the biggest think tank of this period was Bell Telephone Laboratories, Inc., founded in New York City in 1925 as the research arm of Western Electric and the American Telephone and Telegraph Company (AT&T). Bell Labs became a major force of innovation with a strong focus on basic research (as evidenced by the 10 Nobel Prizes awarded to its employees).

In 1962, Bell Labs opened their Eero Saarinen–designed modernist masterpiece dedicated to research and development – an enormous mirrored glass box (dubbed “the Idea Factory”) that eventually contained two million square feet of lab space, set within a large oval landscaped property of nearly 500 acres. Among the countless innovations developed at Holmdel were the Telstar 1 and 2 satellites, which enabled global radio and television communications.

Late 20th Century

Laboratory Design in the Digital Age

Computing power changed scientific research in the second half of the 20th Century.

During WWII, University of Pennsylvania researchers J. Presper Eckert and John Mauchly built the Electronic Numerical Integrator and Computer (ENIAC). In the post-war era, they created their eponymous Ecker-Mauchly corporation, which introduced the landmark Universal Automatic Computer (UNIVAC) in 1951, which was used by the Federal Government to tabulate the census.

IBM followed, introducing their IBM 700/7000 series of mainframe computers in 1952. The early mainframes were powered by finicky vacuum tubes, which generated a lot of heat, necessitating the first generation of “computer rooms” equipped with dedicated HVAC and filtration systems.

After Bell Labs researchers John Bardeen, William Shockley, and Walter Brattain developed a practical transistor design in 1948, the electronics industry began to switch over to transistors, which were more reliable, generated less heat, and were more compact. A further Bell Labs innovation in 1957 was the metal–oxide semiconductor field-effect transistor (MOSFET), which could be miniaturized to such an extent that 10,000 transistors could fit inside a single integrated circuit.

Controversy surrounded the manufacturing of semiconductors. Shockley left Bell Labs and started his own company in 1955, and in 1957, several of his key employees – known as “the traitorous eight” (including Gordon Moore, famous for Moore’s Law and future co-founder of Intel) –bolted to form Fairchild Semiconductor in Sunnyvale, California, a city which would become the heart of Silicon Valley.

Bill Hewlett and Dave Packard, who famously started their eponymous company in a Palo Alto garage, saw the potential in miniaturizing scientific laboratory equipment. In 1972, they introduced the revolutionary scientific pocket calculator, the HP-35, which offered scientists, mathematicians, and researchers an alternative to the ubiquitous slide rule. Texas Instruments (TI), a semiconductor manufacturer founded in Dallas in 1951, joined in the competition by offering its own line of scientific pocket calculators. (As an aside, an unfortunate failure by TI management to offer their Taiwanese-born executive Morris Change a suitable promotion led him to return to Taiwan, where he founded TSMC, today the world’s largest integrated circuit manufacturer.)

The introduction of scientific calculators represented a major step in the digital miniaturization revolution. Equipment in laboratories was becoming smaller and more reliable, with greater functionality thanks to integrated circuit components.

The next logical step was to bring computing power to the laboratory rather than having to rely on leasing expensive mainframe computer time. Digital Equipment Corporation (DEC), located along Boston’s answer to Silicon Valley, the Route 128 Technology Corridor, sought to break through the “big iron” mainframe computing monopoly with their new line of PDP minicomputers, introduced in 1970.

But the biggest revolution in laboratory science computing came with the introduction of the IBM Personal Computer (PC) in 1981, followed by the Apple Macintosh in 1984, which succeeded the popular Apple II introduced in the late 1970s. (The Macintosh’s graphical user interface and mouse borrowed heavily from the work of Xerox Parc, the Xerox think tank outpost in Palo Alto, California.)

The rapid adoption of personal computers in laboratories was revolutionary. Spreadsheet software such as VisiCalc and Lotus123 allowed researchers to record, tabulate, and analyze data, in many cases obviating the need to use expensive time on mainframe computers. Early pre-Internet Local Area Network software (such as Novell) helped researchers exchange data, and sharing information was accelerated by the widespread adoption of the World Wide Web in the 1990s.

The introduction of personal computers (and heavier-duty workstations) required a rethink in laboratory design. Previously, mainframe and minicomputers were housed in separate climate-controlled computer rooms, but these new personal computers could be tucked ad hoc into ordinary lab workspaces.

With a growing reliance on computers and other electronic scientific equipment, there was a realization in laboratory planning circles that the best practice would be to divide lab design into two camps: on the one hand, traditional “wet labs” areas could continue to handle potentially dangerous substances while new data-oriented analysis research functions could be segregated into what became known as “dry labs” or “tech labs” – a distinction that remains to this day.

Lab safety has also received renewed attention during this period, in part due to the advocacy of the Laboratory Safety Institute (LSI), founded in 1978 by Dr. James Kaufman. Thanks to LSI’s awareness campaigns, many commercial and educational labs have redesigned their experimental and safety protocols to prevent accidental fires, explosions, or chemical exposures. Laboratory facility managers have also upgraded or remodeled their facilities to be safer, adding eye wash and emergency showers or removing hazardous asbestos materials that were once commonly used in lab countertops, fume hood fireproofing insulation, and acoustical ceiling tiles.

To increase efficiency, lab designs began to create open, shared areas for centralizing access to more expensive lab equipment resources. Modular lab furniture designs were introduced, which, compared to traditional casework, could be installed more quickly and economically. Other innovations, such as mobile lab furniture mounted on industrial casters, afforded lab personnel the flexibility to move workbenches and tables around as needed, while sit-to-stand workstations and desks offered greater ergonomic comfort to lab researchers working long hours.

New lab designs of the period also featured bigger windows and glass wall dividers to improve visible sightlines – either to the outside world or to other areas of the building interior, allowing access to more natural lighting. Many new lab layouts were also reconfigured to allow small groups to work together, a welcome change for young scientists graduating from school, many of whom were educated in laboratory science by working together in small group project settings.

Early 21st Century

As we approached the new Millennium and beyond, new technological innovations helped accelerate scientific discovery. For example, in the early 2000s, some research teams began to adopt electronic software-based notebooks, part of the emerging Laboratory Information Management System (LIMS) category.

The Human Genome Project (which Formaspace helped support), which began in 1990, was completed in 2003; its success brought greater insight into genomic structures and helped pave the way for mRNA vaccines during the Coronavirus pandemic. The discovery of CRISPR/CAS9 gene editing capability during the early teens also opened up new frontiers in drug design and personalized therapeutics. More recently, AI-powered protein prediction software, such as AlphaFold from Google’s DeepMind subsidiary, has successfully predicted the structures of millions of complex proteins, providing researchers with new insights into the natural building blocks of cell structures.

Automation also became more commonplace across the laboratory landscape, with robots in organic chemistry and clinical testing laboratories capable of handling thousands of samples, automatically pipetting them into well plates. PCR machines that can isolate DNA were once the domain of the few who could afford them, but newer machines have also become smaller, cheaper, and more capable, allowing them to be introduced into many wet lab environments.

2024 Future of Lab: On-Carpet vs Off-Carpet

Formaspace Presents “The Future of Lab” at NeoCon 2024

At NeoCon 2024, Formaspace will introduce a new way of thinking about laboratory design.

We are taking the best of contemporary office design, which features creative design layouts that encourage spontaneous, face-to-face meetings, and bringing that to the world of laboratory design.

This new approach is a radical rethink of the traditional approach of segregating lab facilities into their own isolated silos – hidden away from the rest of the organization.

Not any longer.

At NeoCon 2024, Formaspace will break through these old paradigms by introducing a new way of thinking that, for the first time, fully integrates lab spaces into the greater organization – both visually and functionally.

Instead of isolation, think of collision spaces and spontaneous meeting areas that bring researchers face-to-face with professionals working across all job functions.

We call this new way of doing business “On-Carpet vs. Off-Carpet” – thanks to cohesive furniture design concepts that are fully integrated across the entire organization – it’s laboratories without borders.

The only way you will know you’ve entered a laboratory area is to look down and realize you are stepping away from the “on-carpet” office areas into the “off-carpet” laboratory zones.

Eager to learn more?

Join us at the Formaspace showroom (11-124) at the Chicago Merchandise Mart during NeoCon, June 10-12, 2024.

You can also schedule a private tour for you and up to 10 guests. Book now to reserve your preferred time by clicking here.

Formaspace is Your Laboratory Research Partner

Evolving Workspaces. It’s in our DNA.

Talk to your Formaspace Sales Representative or Strategic Dealer Partner today to learn more about how we can work together to make your next construction project or remodel a success.