As consumers have increasingly come to rely on overnight delivery, there is an enhanced pressure on supply chain management teams to get their distribution centers in line with semblance of urgency. Packing Stations are a potential bottleneck in the process, so more and more attention is being paid to improving their material handling efficiency.

This week, we countdown the top 13 ways that Packaging Stations have changed for the better.

Let’s begin our countdown, starting with number 13: Customized Packing Stations Designed for Different Tasks.

#13. Customized Packing Stations Designed for Different Tasks

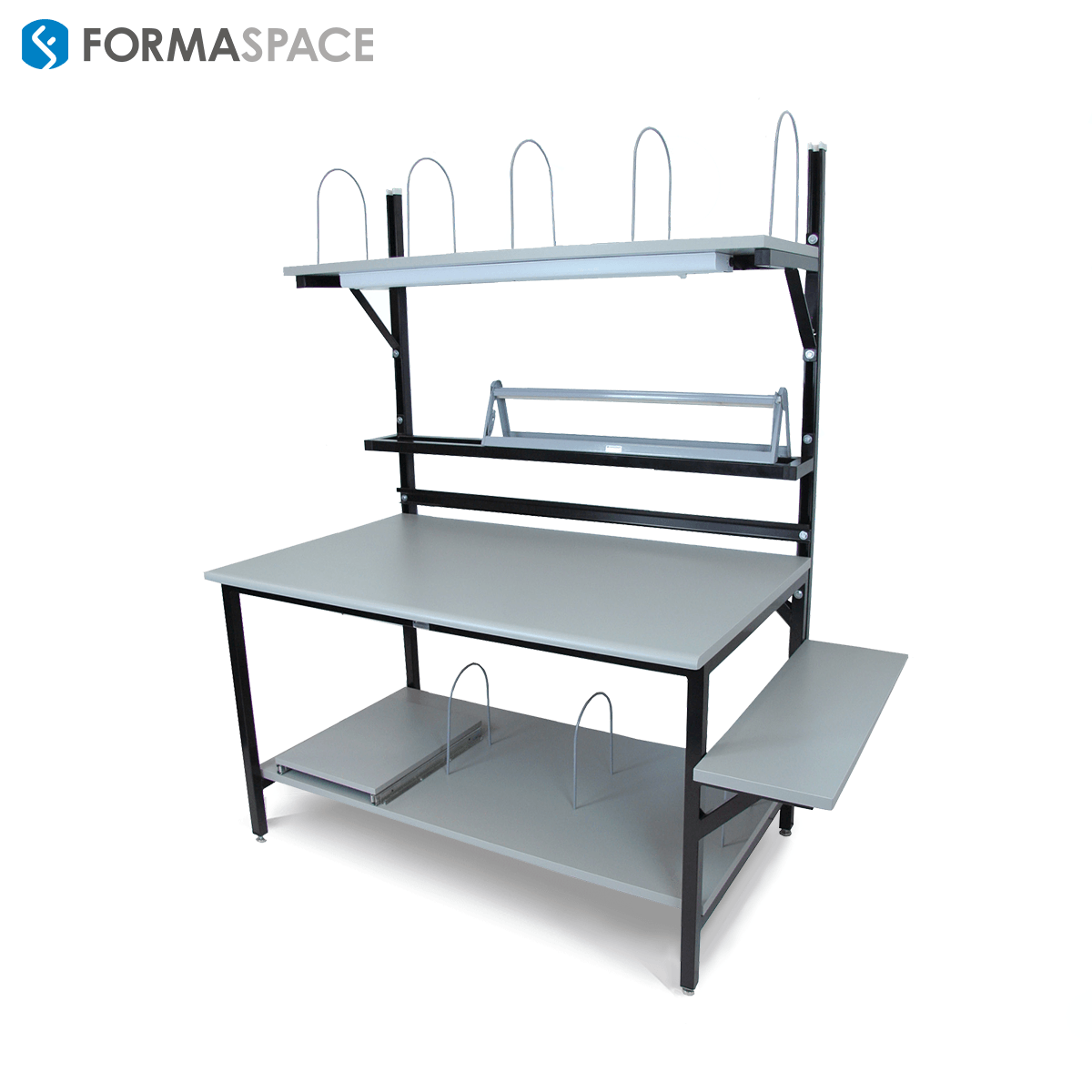

Where packing stations used to be fairly uniform from distribution center to distribution center, specialization is the new byword in packing station design. Heavy or bulky items are now often segregated from smaller, light items. In contrast, bulky items are sent to packing stations with large tables built for heavier SKUs. Meanwhile, shippers working with smaller, lighter items can work more rapidly — by taking fewer steps — at compact packing stations designed to fit smaller, high-volume shipping boxes.

#12. Automatic Height Adjustment for Different Stature Operators

Lower back pain, shoulder pain, repetitive stress injuries — these are all examples of the types of on-the-job injuries we strive to avoid in distribution centers. Fortunately, just as packing stations are become customized for individual tasks, it’s become more and more common for packing stations to be customized on the fly for individual operators.

Height adjustable work surfaces are becoming one of the most requested features here at Formaspace. How do they work? Easy to access controls are installed that can adjust the height of work surfaces at the touch of a button. Our motorized furniture solutions, using hydraulic power, allow your employees to choose the right height to match their physical stature, reducing the potential for injuries. You owe it to your employees to try it out.

#11. Power-Assisted Loading for Heavy Items

Power assisted-loading is another key way that modern picking and packing stations have advanced. Whether it’s powered shelves, vertical lift modules (VLM) or horizontal carousels, just about any storage solution can be equipped with a power-assist to help your pickers and packers handle those heavy or extra-bulky items safely and securely. These power-assist lifts can help reduce common injuries (such as lower back pain) or prevent accidents (like dropping heavy items on an operator’s foot.)

#10. Systematic Elimination of Extra Steps at the Packing Station

As consumers continue to show their preference for expedited overnight delivery, supply chain management experts have looked high and low for ways to wring out every last bit of efficiency in distribution center packing and shipping operations. Packing stations, in particular, have come under intense scrutiny. The workflow is constantly being analyzed and fine-tuned to reduce any extraneous steps — whether it’s operational steps (e.g. handling and re-handling inventory) or footsteps (e.g. steps taken by the operator walking back and forth to reach for items.) As a result, the latest packing station layouts utilize very clever storage solutions, such as arranging packing materials in a 360 path that ‘surrounds’ the operator — in order to provide everything at hand while reducing the number of unnecessary employee steps during the work shift.

#9. Influence of Omni-Channel Retail Packing and Overnight Delivery

There used to be clear boundaries between catalog operations and retail stores. Even during the days when Sears Roebuck’s catalog business reigned supreme, they pretty much kept their catalog business separate from their retail operations. This separation continued through the early days of electronic commerce on the Internet —but things are changing quickly.

Today’s innovative retailers understand that combining their distribution center operations and retail locations gives them a strong competitive advantage. This “Omni-Channel” approach allows consumers the ability to do things like order online and pick up (or return items) at their local store — often in the same day.

Of course this close integration greatly increases the operational challenges for supply chain management. For example, local outlets (which happen to have an online customer’s inventory item in stock) are increasingly required to ship out inventory directly to consumers — a task once handled by the major distribution centers. As a result, retail locations and local warehouses are having to ‘up their game’ to meet the speed and complexity of new challenges posed by consumers. The end result is many retail locations are upgrading their shipping operations by installing dedicated packing stations once only found in large warehousing operations.

#8. The Rise of Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS)

Different system vendors have come up with a variety of integrated systems to make sense of the product intake, storage, transportation, identification, tracking, picking, routing, order consolidation, packing and shipping activities. These systems, known variously as Warehouse Management Systems (WMS) or Warehouse Control Systems (WCS), are often proprietary solutions that help automate and track inventory as it passes throughout the distribution center. Some of these proprietary solutions involve innovations such as custom designed carousels, totes and conveyors to speed order picking and transportation to the packing station, as well as automated tools to help the operator pick inventory, which we will review in the following section.

(We’ll also cover AS/RS — Automated Storage & Retrieval Systems — in a section further down below.)

#7. Visual and Auditory Cues for Picking Operators

Many of the WMS / WCS solution providers have introduced specialized tools to help operators pick and put inventory. These advances are broken down into a few categories:

-

Barcode systems with a hand held wand or sensors:

These devices were among the first tools available.

They allow verification of picking and packing. -

RFID Tags

Infrared Tags allow close range tracking of inventory and can be used in tandem with visual and auditory cues.

-

Visual Cues: Pick to Light, Put to Light

Complex warehouse solutions use a variety of light systems (often LED lamps) to guide pickers and packers to inventory bins to pick SKUs.

-

Auditory Cues: Voice Activation

More recently, synthetic computer voices provider operators wearing headsets with verbal commands for picking and packing inventory

-

Heads Up Displays:

On the horizon are Google Glass-style heads up displays to help operators find and confirm inventory SKUs for picking and packing.

#6. Evolution of Batching Techniques in Supply Chain Management

The introduction of different batching techniques has had a big effect on the productivity of distribution center picking and packing throughput.

The simplest technique, known as Discrete Picking, came onto the scene first. This technique is very basic: one customer order, one picking operator, one packing operator. This Discrete Picking approach makes sense intuitively: for each customer order, there is one picker who traverses the warehouse to collect the order items. Once everything is collated, it’s sent to the packer. Each item is handled a minimum number of times.

But in most high-volume cases, the Discrete Picking process is far from the fastest method. Experience has shown that running parallel operations in batches with more than one picker can move inventory through the distribution center much faster than relying on one order/one picker alone.

These parallel batch picking processes are broken down into many different sub-categories. Some of the main approaches include:

-

Zone Picking (and a variation known as ‘Pick and Pass’):

Pickers cover a geographic zone within the warehouse, which are combined with picks from other zones to complete an order.

-

Batch Picking:

Pickers pick the same SKU to fulfill multiple orders, then moves to next SKU.

-

Cluster Picking

Pickers pick multiple items into multiple container bins, totes or shippers (e.g. shipping boxes).

#5. Predictive Cubing Solutions

A recent packing table innovation is to anticipate the volumetric size of an order before packing. This way the proper ‘shipper’ (e.g. shipping container, often a cardboard box) can be staged for packing.

How does it work? Predictive cubing relies on storing volumetric data for each SKU in the warehouse inventory database. A computer program pulls the data and can predict the best fitting ‘shipper’ to use to pack the combined order. This approach reduces waste in at least two scenarios:

-

Picker chooses undersized Shipper (box)

When the packer starts out packing into too small a shipper (box) and either starts over with a larger shipper (with time lost) or ends up sending the order out in two shippers (boxes) (with postage wasted).

-

Picker chooses over-sized Shipper (box)

In this case, the packer has to use extra fill material to secure the materials inside the ‘shipper’ (box), and the total shipping cost may be unnecessarily high due to the increased overall dimensions.

#4. Printing Documents on the Fly

This innovation really helps throughout the packing station. Custom printers can create and insert documents into each shipment as they are packed. This innovation allows marketing departments to include custom coupons, personalized special offers and other documents including manuals and instructions in each shipment. Printing on the fly reduces on-hand inventory, reduces errors and allows each customer to get their own custom information.

#3. Rise of Robotic Automation

AS/RS (Automated Storage & Retrieval System) installations have been around since the 1960s. The basic versions, also known as automated storage and retrieval machine (SRM) installations, include various configurations, such as Fixed Aisle layouts and Carousels/Vertical Lift Modules (VLMs). These installations facilitate maximum utilization of warehouse space.

Robotics and automation have taken these AS/RS systems to the next level. We’ve written before about the Kiva solution, purchased by Amazon and now known as Amazon Robotics. This integrated system significantly reduces manpower requirements for picking and staging inventory for packing tables. In fact, Amazon considers the Kiva technology such a competitive advantage that they will stop offering the technology to competitors by 2019 and will only develop it for use in-house. This has forced warehouse operators who used Kiva solutions to scramble for a replacement from other vendors, such as Grenzebach Group, Harvest Automation, Grey Orange, Fetch Robotics or Locus Robotics.

#2. Smartphone Integration in Supply Chain Management

The arrival of smartphones, like the iPhone from Apple, which have multiple capabilities — such as Internet data access, Geo-location (GPS), integrated camera (scanner) capability and built-in microphone and speakers — have put pressure on dedicated, single purpose hardware provided by Warehouse Management Systems (WMS) vendors. Many WMS customers were getting sticker shock from the prices they were charged for expensive single-purpose dedicated equipment, when it’s plainly clear that their smartphone could serve the same purpose at much less cost.

Consequently, we are in the midst of major changes as WMS vendors and new startups wanting a slice of the business begin to leverage the integrated capabilities that smartphones offer.

#1. Artificial Intelligence and Big Data influencing Packing Tables

As we’ve discussed before, many major retailers are trying to speed up delivery to consumers. Now that overnight delivery has become an accepted practice, many of the big players want to speed things up even further – even delivering in just a few hours after the order is placed in highly urban areas.

How can this be achieved?

Delivery by drone aircraft has piqued the public’s attention.

But automation through artificial intelligence and big data may play an even more important role than drones. Retailers like Amazon are trying to build up a personal dossier on each of their customers so they can anticipate when they will place an order for a product; with these predictions, Amazon can pre-stock the inventory at strategic locations.

But today, this big data approach goes even further. Thanks to their Amazon Echo device for the home (and the competing Google Home device from Google), Amazon can collect information instantaneously when a consumer asks for it. When a customer speaks to the Echo device asking about product information before making an order, the big data tools can process and add this information to the consumer’s profiles, which in turn feeds into a supply chain management ordering forecast.

In a way, this is just an extension of the type of automation occurring in the distribution center itself, just extended upstream into the consumer’s home.

Ready to up your game in the overnight delivery world? Take a look at Formaspace Packing and Shipping Station solutions.

Formaspace is a leading provider of professional packing and shipping stations. Email us today at hello@formaspace.com and speak with one of our experts. We can create the right solution to match your distribution center needs.