In the past, many U.S. startup companies looked to contract out their manufacturing operations to factories in Southeast Asia. But the increasing cost of overseas labor, concerns about product quality, delays in shipping product across the Pacific, and Washington’s new proposed tariffs on imports are convincing more and more companies to open manufacturing operations in the U.S.A. But what’s the right way to get started? We take a look at 10 factors to consider when planning your new domestic manufacturing facility.

“If a foreign country can supply us with a commodity cheaper than we ourselves can make it, better buy it of them with some part of the produce of our own industry, employed in a way in which we have some advantage.”

Adam Smith, The Wealth of Nations (1776)

If you studied economics, no doubt, you’re familiar with Adam Smith (and his philosophical successor, David Ricardo) and the “comparative advantage” theory of international trade. As a trading nation, China has learned these lessons well. By taking advantage of its comparative advantage – low labor costs – China created some of the most productive manufacturing clusters the world, displacing the USA as the world’s leader in value-added manufacturing output back in 2010. But labor costs are rising in China and other low labor cost countries around the world. This is starting to make American manufacturing more competitive, particularly when indirect cost, such as long lead times, transportation, etc. are taken into account. And when you add in the uncertainties due to the threat of increased tariffs on imported goods,* we have now reached a tipping point where it makes sense to manufacture a greater number of goods in the USA.

(*See our recent article for detailed analysis on how tariffs are affecting the furniture manufacturing business.)

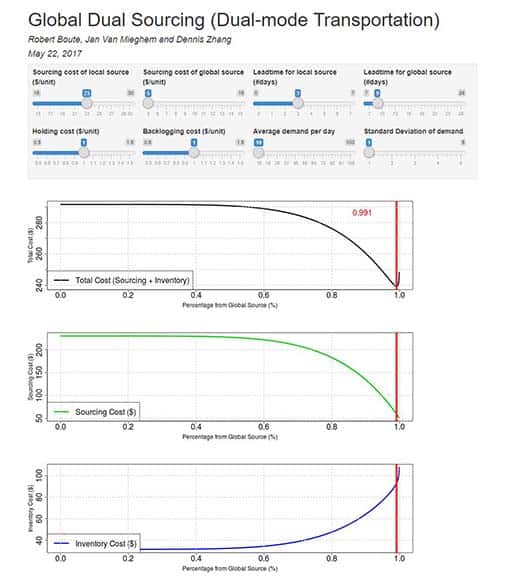

Economic researchers at the Kellogg Business School at Northwestern University have been investigating this tipping point, trying to quantify exactly when it makes economic sense to manufacture products domestically. (You can try out their economic model for yourself.)

In a nutshell, products that are the best candidates for re-shoring to US manufacturing facilities include: high-value-add products (where labor costs are a smaller percentage of the total cost of goods or COGs), products produced on highly automated manufacturing lines (also with relatively less labor COGs), heavy or bulky products that incur high transportations costs, or goods that need to be delivered to customers quickly.

If the economics look promising, it’s time to move on to creating a plan. Here are the top ten considerations you need to take into account when starting up a new manufacturing plant in the USA:

1. Find a Niche Market to Sell Differentiated Products

Rather than competing on price alone, many of the successful new American manufacturing companies have found a hole in the market to fill with unique, differentiated product offerings.

Take Weiss Watch Company, for example. It’s a new high-end, American-made luxury goods manufacturer with a factory workshop in Los Angeles, where they build each of their timepieces in the tradition of great Swiss watchmakers. (Each watch requires assembling 150 tiny pieces to create the mechanical movement, a process that takes 35 hours.)

Meanwhile, Cortex Composites has invented a “better mousetrap” that’s making waves in the concrete business. Their unique concrete product can be rolled up for easy transport and then wetted for use on site; this eliminates the need to dispatch an expensive concrete mixing truck on many smaller construction projects.

Manufacturing companies are also introducing business models that leverage the power of the internet. Xometry is an example of this new wave of internet-powered business models: it’s an on-demand manufacturing platform that allows companies to tap into the reserve manufacturing capacity of thousands of American machine shops and factories for quick turnaround production.

Manufacturing companies are using internet community forums to engage with their customers in the design process, an approach known as ‘co-creation.’ (Perhaps you are aware that Formaspace Office is a leader in the co-creation process for the custom office furniture market.) Another example of co-creation is the hipster apparel company Threadless, which solicits individual graphic art submissions for its clothing lines that are voted on by the community.

2. Learn the Ins and Outs of the Manufacturing Business

To be successful in an industry as complex as manufacturing requires a commitment to lifelong learning to keep up with ever-changing manufacturing technologies, customer requirements, supply chain operations, and governmental regulatory regimes.

But how do you get started?

The answers are as broad as the manufacturing industry itself.

Some of the famous names in manufacturing are natural-born inventors who got their start by developing new products on their own, such as Hewlett and Packard who created their first electronic device in a Palo Alto garage, or Yvon Chouinard, founder of Patagonia, who began sewing clothing in a chicken coop converted into a workshop.

College and university degree programs in industrial engineering, product design, mechanical engineering, robotics, computer science, and other technical areas can provide a solid foundation for managing manufacturing businesses (Degrees in business administration, systems operations, economics, and marketing can be just as valuable.)

Hands-on experience in making things can help pave the way to success. Fortunately, today’s colleges and universities are offering greater access to Makerspaces, where one can gain invaluable experience prototyping and refining design concepts. Business incubators and accelerators that specialize in hardware products, such as Make in LA, provide direct access to industry experts and advisors who can help you bring a product concept to market.

Manufacturing internships and apprenticeships are also important pathways for those wanting to master a particular industry. For example, Cameron Weiss of Weiss Watch Company apprenticed at two famous watchmakers in Switzerland to learn the art of making high-quality mechanical watches before he started his company.

Bringing on consultants and advisors to give you professional advice is another important option. For example, Formaspace can help you design the layout of your new warehousing facilities, distribution centers, and manufacturing lines – to achieve maximum efficiency for your operations while maintaining a safe, ergonomic environment for your workers.

3. Pitch Your Business Plan to Investors

Bankers and investors (or board members of a company) will have a lot of questions to ask you before deciding to help find your new manufacturing venture:

What products are you going to sell exactly and for how much? How do your products compare with the competition? What is the length of the customer sales cycle? What are your sales projections for the next six months? What about in one year, three years, and five years out? How much material inventory will you need to keep on hand to meet your production needs? Where can you lease a facility for production and how much will it cost? What about equipment costs? What are the financial projections for earnings before interest, tax, depreciation, and amortization (EBITDA), and what will be the return on the initial investment?

In order to answer their questions with credible answers, you’ll need to write a detailed business plan that makes the case for your new manufacturing business.

In addition to answering the some of the questions above, you’ll also need to consider what regulatory regimes you fall under for your particular industry, such as manufacturing practices, product safety standards, environmental rules, employee health and safety, taxes and investment credits, etc. You’ll also need to identify customers who will buy your products, supply chain partners who will supply raw materials and components, and a sales channel (more on these later) who will sell your products to the end user.

And once the first draft of the business plan is assembled, it’s time to summarize it into a short explanation, commonly known as the elevator speech, which allows you to present a succinct, credible pitch in under a minute or two that helps convince investors or bankers to fund your new manufacturing business.

4. Select the Best Location for Your Manufacturing Operations

Selecting the best site for your new manufacturing facility is a challenge that will require extensive due diligence.

To help you get started, be sure to review our special report on How to Select the Location of Your New Manufacturing Plant. In this document, we take a look at the hard cost factors to consider, including

- Access to customer markets

- Proximity to supply chain infrastructure

- Effective corporate tax rates and incentives

- Business regulatory regimes

- Customs and trade agreements

- Business operating costs, including real estate, utilities, and prevailing wages and benefit costs

We also took a look at indirect and other soft cost factors to consider, including

- Industry clusters with access to knowledgeable manufacturing workers

- Business and government transparency

- Cost of living

- Quality of life, including educational institutions, recreation, and leisure

5. Use Lean Manufacturing Techniques to Optimize Production

To keep up with the competition, today’s manufacturing facilities need to maximize productivity, quality, and efficiency.

The answer is, it depends. All of today’s leading best-practices for manufacturing, including Kaizen/ Toyota Production System, Lean Manufacturing, Six Sigma and Lean Six Sigma, can trace their roots back to Japanese car manufacturers who (after World War II) began to incorporate statistical research methods for the production line pioneered by W. Edwards Deming, an American who is revered in Japan to this day.

These approaches emphasize continuous improvement, just-in-time manufacturing methods, worker involvement in the manufacturing process, long supply chains, and sophisticated quality control programs.

Formaspace can help you create a sophisticated, productive lean manufacturing environment. (We’ve built furniture solutions for renowned Fortune 500 industrial manufacturing and distribution companies, such as 3M, Amazon, Apple, Boeing, Dell Computer, Keuhne+Nagel, Lockheed Martin and McMaster-Carr Supply Company.)

We offer a Rapid Plant Assessment service, in which we visit your site and make recommendations on how to improve the flow of your warehousing systems, your material handling, manufacturing lines, packing stations and more. Learn more about our Rapid Plant Assessments (RPA) here.

Design details in the layouts of your manufacturing lines warehousing and distribution centers are also critical factors for success. We’ll take a look at those next.

6. Create an Efficient Manufacturing Line in Your Assembly Plant

As you are no doubt aware, Formaspace builds custom industrial furniture solutions for both major fortune 500 companies as well as smaller startup manufacturers.

What can we build for you?

Depending on your needs, you’ll probably be interested in one or more of these items – built to your unique specifications here at our Austin, Texas factory headquarters using American-made steel other locally sourced products:

- Heavy-duty and light-duty manufacturing workbenches (including workbenches with complete ESD detection built-in for handling sensitive electronic components).

- Stainless steel workbenches in other furniture for use in clean room environments or in other sensitive environments, such as pharmaceutical manufacturing or food and beverage production.

- Custom tool benches, tool trolleys, tool balancers, and storage systems to keep tools organized and in good condition.

- Storage systems from bin rails to shelves and cubbies, to custom cabinets – all designed to keep everything in its place for efficient operations.

- Industrial storage racks and flow racks to keep raw materials organized and stored safely.

- Custom picking and packing stations to optimize your warehousing and distribution center operations.

- Heavy-duty and light-duty mobile carts to transport heavy and/or sensitive equipment while reducing on-the-job employee injuries.

- Custom integration solutions, such as integrating workbenches with conveyor systems, or integrating equipment, such as scales, into workbench cutouts.

Each of our products can be customized, including the worksurface. Read more about our worksurface material choices here.

We also offer ergonomic solutions to help reduce injuries on the job, such as our height-adjustable, sit-to-stand workbenches, tables, and desks.

Why not check out the 3DConfigure tool from Formaspace? This free browser-based tool (no download is required) allows you to create your own furniture designs in minutes. Use 3DConfigure to produce photorealistic images of your furniture designs, including all material and finish choices, colors, as well as storage and convenience options.

7. Build an Effective Sales Channel to Find Customers to Buy Your Products

As part of your business plan, you (hopefully) were able to identify key customers to buy products from your new manufacturing facility.

That’s where the sales channel comes in: this is the operational system that connects your products offerings with willing buyers.

In the pre-internet days, there were fewer options for creating a sales channel. At that time, companies generally fell into one of two categories, either business-to-business (B2B) operations, which as the name implies sells its goods to other companies (typically as part of larger supply chain), or business-to-consumer (B2C) companies, in which the manufacturer sells to the consumer, either directly or indirectly.

In the classic B2B category, companies often create a sales channel that relies on its own employees to sell their products (direct sales), or they may employ third-party distributors, dealers, or value-added resellers (VARs) to sell their products. (In the latter cases, these outside sales teams are often assisted by the company’s inside sales team, which may also handle the largest key customer accounts directly.)

In the classic B2C scenario, companies need to create a sales channel that maximizes reach to consumers. To accomplish this, many companies turn to an indirect sales channel, e.g. distributors and wholesalers who, in turn, sell the products to retail stores. Or B2C companies might invest in brick-and-mortar stores to sell their products directly to consumers or publish catalogs for consumers to order products direct from the factory. Many B2C companies rely on all these strategies (and more) in what’s known as an omni-channel approach to sales.

Of course, in the age of the internet, things have changed. Catalogs sales have morphed into online website storefronts, allowing both B2B and B2C companies to automate the sales ordering process, leading to the relative decline of brick-and-mortar stores. B2B companies are also increasingly using the internet to establish direct connections to their end user customers.

However, face-to-face sales relationships are as important as ever. Despite the efficiency of the internet, most manufacturing companies still rely on top-notch sales people to maintain a close relationship with key strategic accounts, as well as education, government agencies, and the military – due to their unique purchasing requirements.

8. Attract (and Retain) Employees with the Skills You Need

There is a nationwide shortage of available employees who have the technical skills necessary to work in today’s modern manufacturing facilities.

We’ve written extensively about this topic. Be sure to read our report on How to Attract Talent to Industrial Facilities for specific recommendations.

What is the solution?

In the long-term, we need to encourage more students to take science, technology, engineering, and mathematics (STEM) courses in school.

In the short term, savvy manufacturing companies are reaching out to educational and vocational institutions to identify young people and employ them in internships and apprenticeships, so that they can grow into a long-term manufacturing career. Makerspaces and business accelerators are other fertile areas that manufacturing companies should investigate to find prospective workers.

Manufacturing companies also need to overcome the perception that manufacturing jobs are low paid and low status, and the working conditions are dirty and physically demanding. In fact, for many high-tech manufacturing operations, the opposite is true: the jobs are well paid, they require sophisticated technical skills, and there’s long-term job stability.

Women, which represent 50% or more of the perspective workforce, are even less disposed to consider manufacturing careers than men. Companies need to take specific steps to encourage women to pursue STEM careers and to take jobs in manufacturing.

At some companies, there may be an unwelcoming culture for women on the factory floor. See our report on How to Build a Better Culture in Your Manufacturing Facility for specific ways to make your employees feel engaged and empowered at work.

9. Find the Right Partners to Help Grow Your Business

When venture capitalist (VC) firms invest in startup companies, they often look beyond an individual founder for the product idea to zero in on the composition of the entire team.

In other words, they are generally less interested in investing in a specific product concept or individual person – rather, they make a decision on whether to invest in a group of people that have a range of complementary skills that work well together and are motivated to achieve success.

Building such a team may be the greatest and most rewarding challenge facing anyone contemplating creating a new manufacturing facility.

10. Formaspace is your Competitive Advantage

Formaspace stands ready to help make your new manufacturing venture a success.

Working together, we can design and build custom solutions that will make your production line warehousing, and distribution centers work at maximum efficiency while creating an environment that is welcoming to your workforce and insures their health and safety on the job.

We count among our customers some of the leading Fortune 500 industrial manufacturing and distribution companies in the world, including famous names such as 3M, Amazon, Apple, Boeing, Dell Computer, Keuhne+Nagel, Lockheed Martin and McMaster-Carr Supply Company.

Take the next step. Contact your Formaspace Design Consultant today and find out how we can help you.