If you were lucky enough to see a string of lights in the sky in late May (not a battalion of UFOs as many initially feared but rather the first vanguard of Elon Musk’s new Starlink satellite fleet), then you witnessed the dawn of a new era in low-cost, low earth orbit mini-satellites. We take a look at how student-led teams and startup companies alike are revolutionizing (and democratizing) human communication and scientific discovery — by building and launching their own mini-satellites into space. We’ll also walk through some of the key Formaspace makerspace solutions for prototyping and manufacturing components for this new class of low-cost spacecraft.

Mini-Satellites and the New Economics of Space

Who controls the market for the latest satellite space technology?

You could be excused if you thought it was a member of the “billionaire boys space club,” which includes the late Paul Allen (Stratolaunch), Richard Branson (Virgin Galactic), Amazon* founder Jeff Bezos (Blue Origin), Fatih Ozmen (Sierra Nevada Corporation), and Elon Musk (SpaceX*).

(*Amazon and SpaceX are Formaspace customers.)

Enter the mini-satellite.

Unlike their big brethren orbiting occupying the higher, prime real estate of geosynchronous orbit, these maverick new micro spacecraft (variously known as cubesats, nanosats, or mini-satellites) roam around the planet at much lower altitudes.

The combination of low weight and low earth orbit is a golden ticket in space launch terms, making it economically viable to piggyback mini-satellite “stowaways” on existing private commercial and government-funded space launches.

Small is Beautiful

In an effort to open up space access to a wider group of stakeholders, NASA* created the CubeSat Launch initiative (CSLI) whose mission is to provide “a low-cost pathway (for educational institutions and non-profit organizations) to conduct research in the areas of science, exploration, technology development, education, or operations.”

(*NASA is a Formaspace customer)

Since the program got off the ground (literally) in 2010, NASA has put 85 mini-satellites into space (with dozens more waiting in the queue). They hitch a ride on regularly scheduled government payloads destined for the International Space Station, or on other space launches chartered by NASA.

Mini-Satellite Quick Facts

- Satellite volume is measured in “U” units (equal to 10 x 10 x 10 cm)

- Common satellite form factors are 1U, 2U, 3U, or 6U box volumes

- Most satellites weigh less than 3 pounds per U

- Satellite hardware costs start in the low $10,000s and go up

- Launch fees range from $30k to approx. $300k

- Timeframe from concept to space operations in as little as 18 – 36 months (launch delays can add months to schedule)

- Earth to satellite communication is via ordinary UHF and Ham radio bands

- Satellites must be designed to burn up upon reentry to avoid contributing to the “space junk” problem

(Want to keep track of the latest launches and satellites in operation? Check out NASA’s manifest list, the Nanosats.eu website, and Jonathon’s Space Report for the latest operational details.)

College and University Science Teams Building and Launching Mini-Satellite Projects

Many of the colleges and universities participating in NASA’s CubeSat program are Formaspace customers.

We’d like to highlight a few of our educational customers with advanced mini-satellite programs underway, at Cornell University, MIT, Northwestern University, UC Berkeley, and the University of Texas at Austin:

Cubesat Programs at Cornell University

Cornell University has deployed several cubesat projects, including the Pathfinder for Autonomous Navigation (PAN) program — designed to demonstrate docking two cubesats together in low earth orbit — and the KickSat program.

Funded by a Kickstarter campaign, Cornell’s KickSat-2 (3U) satellite carried over 100 experimental “ChipSat” sprite satellites on board, launching them into low earth orbit from space. These mini “femtosatellites” only operate for a few days but may develop into an important solution for rapid space communication and surveillance deployment.

Finally, an upcoming Cornell project is the Cislunar CubeSat, which will evaluate a new propulsion system using water and electricity. The electricity separates the water into hydrogen and oxygen, which are then burned as a conventional fuel-based propellant.

Cubesat Programs at MIT (Lincoln Laboratory)

Following the launch of MiRaTA project, MIT’s Lincoln Laboratory is planning to launch several new cubesat spacecraft.

The Time-Resolved Observations of Precipitation structure and storm Intensity with a Constellation of Smallsats (TROPICS) mission will launch a fleet of mini-satellites designed to investigate hurricane formation by measuring storm system thermodynamics in the troposphere, using high-performance radiometer scanning to capture temperature, water vapor, and cloud ice measurements.

The BeaverCube is an MIT educational mission designed to introduce high school students across the nation to aerospace science and technology through a hands-on project. The resulting satellites will measure cloud properties, ocean surface temperatures, and ocean color to study Earth’s climate and weather systems.

Finally, the CubeSat Laser Infrared CrosslinK (CLICK) mission will demonstrate the feasibility of establishing full-duplex laser communication between two low earth orbit 3U cubesats, with data rates of up to 20 Mbps at separations from 25 km to 580 km.

Cubesat Programs at Northwestern University

Northwestern University’s upcoming SpaceICE mission will evaluate techniques for the manufacturing of complex structures in low earth orbit using a “freeze casting” method. Freeze casting is rather different from the traditional “lost wax” casting method in that it uses a temporary structure (made of ice) that forms the exterior mold surface (rather than the lost wax method, which creates the ‘voids.’) Once the titanium solution solidifies into a solid, the ice is melted away to reveal a complex structure that would be difficult to produce using traditional separable molds.

Cubesat Programs at UC Berkeley

Berkeley leads the international CINEMA program whose mission is to create a roadmap of space weather conditions. Several CINEMA satellites will work together to map out “magnetospheric constellations,” e.g. areas with high concentrations of electrons and ions that are associated with electron microbursts, auroras, and other magnetic fields phenomenon.

The CUbesat Radio Interferometry Experiment (CURIE) is another Berkeley cubesat program. When launched into space in 2020, the CURIE satellite will split into two separate cubesats, and then fly in formation to measure low-frequency radio waves (0.1-19MHz), which cannot be detected from the ground due to the Earth’s ionosphere. CURIE hopes to study radio burst emissions from solar eruptive events, such as flares and coronal mass ejections (CMEs) in the inner heliosphere.

Cubesat Programs at the University of Texas at Austin (Texas Spacecraft Laboratory)

The ARMADILLO (Attitude Related Maneuvers and Debris Instrument in Low (L) Orbit) is designed to detect impacts (measuring strength, location, and direction) from sub-millimeter sized space dust and debris particles found in low earth orbit.

Mini-Satellite Startup Companies Join Space Giants in Low Earth Orbit

A new class of space exploration startup companies has emerged, launching mini-satellites into low earth orbit.

The results are impressive.

Take Planet Labs, for example. This San Francisco-based startup launched 64 satellites into space last December on a SpaceX rocket, adding to its 140 strong mini-satellite fleet.

Among Planet’s early accomplishments was the mapping of the rapidly developing Camp Wildfire that devastated the Sierra foothills town of Paradise, California in November 2018. Unlike expensive geo-stationary satellites (which typically scan a particular spot on earth every few days), Planet’s mini-satellites were able to provide rapid updates of the fire containment operations, helping to save the lives of evacuees and firefighters.

Another space startup, Capella Space, has created a mini-satellite capable of receiving and “bouncing” radar signals from Earth, a feat once only imaginable on full-size satellites. Notably, Cappella’s antenna is a not only a feat of impressive engineering, it’s also a work of art — an origami artisan was employed by the company to fold its 100 sq foot antenna to fit inside the tight confines of its launch container.

New Miniaturized Capabilities are Making Mini-Satellites More Powerful

Advances in mini-satellites are following in the footsteps of smartphones (and PC computers that proceeded them) by putting more and more technology into a smaller footprint.

Unlike traditional satellite programs, which rely on military/space grade equipment, the new low earth orbit mini-satellites often rely on commercial off-the-shelf components (known as COTS) destined for consumer electronics products — they are often cheaper, more readily available, use minimal power, and get updated with new generations of technology more quickly.

This approach has allowed satellite developers to deploy a wide range of sophisticated technology that’s embedded in a chip, from high-quality optical cameras to non-visual spectrum sensors, e.g. radar/lidar.

Companies such as ACCION are taking this “kit on a chip” approach one step further. Their new “thruster chip” technology is a rocket motor mounted on a chip: each chip houses hundreds of microscopic emitters.

ACCION’s technology applies an electric field to each emitter, creating a beam of ions that are guided through individual extractor holes (think individual micro nozzles). The result is sufficient “thrust” necessary to move mini-satellites in space.

Formaspace Cleanroom Solutions for Spacecraft Manufacture

Let’s take a look at some recent Formaspace custom solutions used in spacecraft manufacturing and deployment.

Preventing contamination is an important consideration when developing new spacecraft destined for launch.

We built a set of four of these custom stainless steel workbenches destined for the pre-launch cleanrooms at an important client on the Florida Space Coast. (By request, they prefer to remain anonymous.)

See our report on cleanroom technology for more information.

Formaspace ESD Solutions for Spacecraft Equipment

Even the smallest static electrical discharge can destroy or significantly curtail the operational life of microelectronics.

That’s why Formaspace created its unique Electrostatic Discharge (ESD) solution — a full worksurface with built-in ESD protection. No more hassle with small ESD mats, the entire working area is protected.

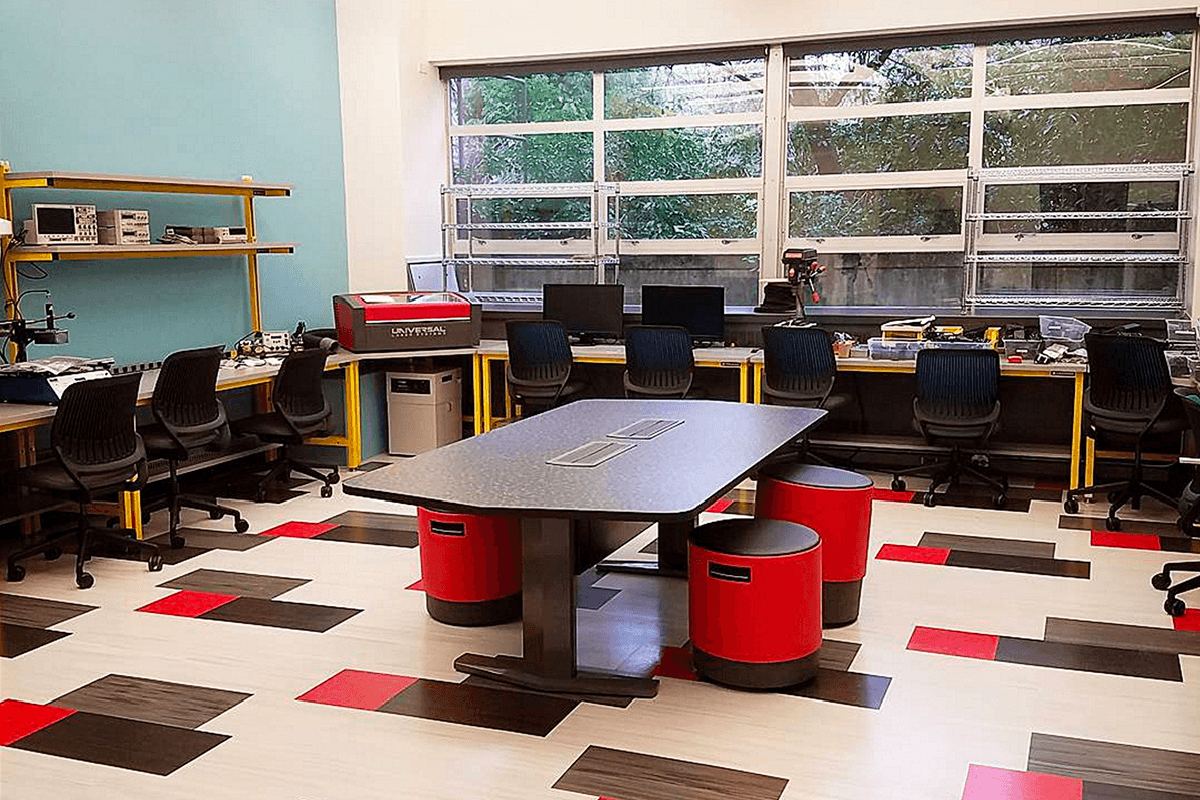

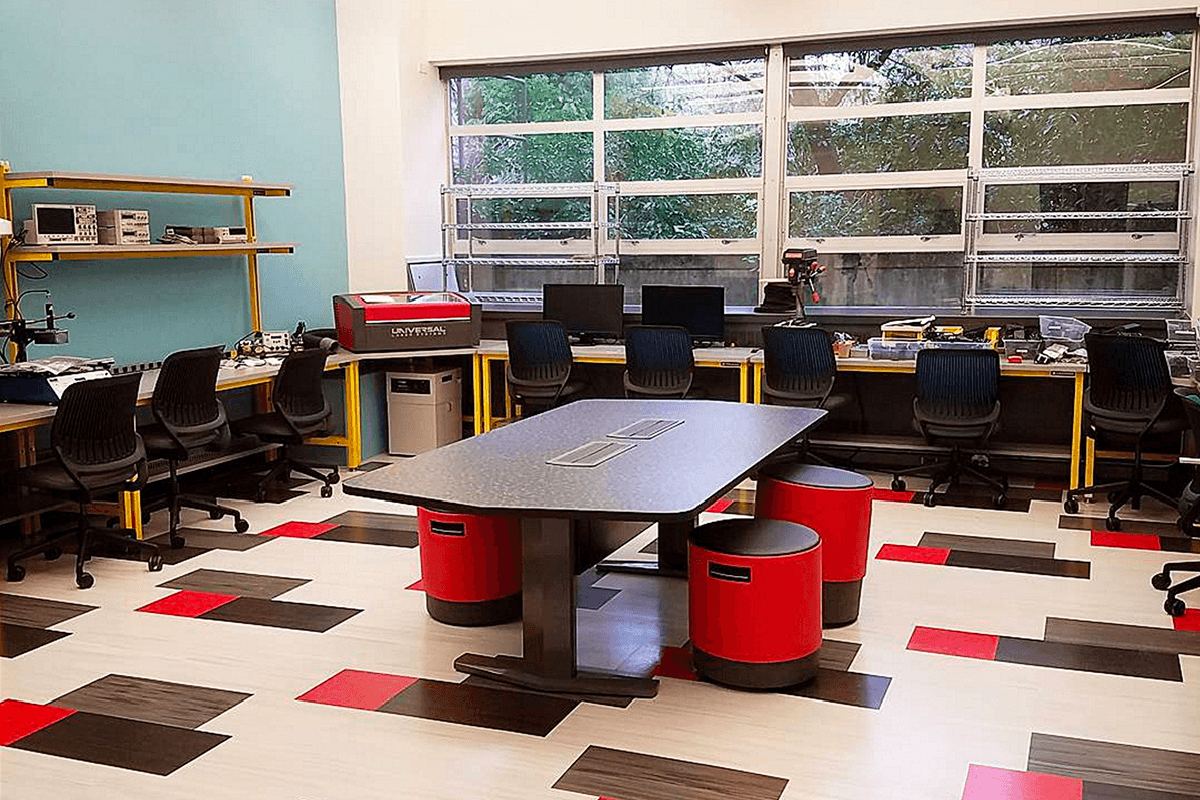

Formaspace Makerspace Solutions for Spacecraft Design and Development

When it comes to creating a safe, productive environment for aerospace and electronic prototyping and manufacturing, Formaspace has you covered.

Talk to your Formaspace Design Consultant about our innovative makerspace solutions. They are the ideal solution for teams of aero engineers and up-and-coming university and secondary STEM students as well.

Keep your tools and equipment neat and organized. Work safely and securely on our heavy-duty workbenches, tables, and stands.

Formaspace is Your Partner for Innovative Solutions

If you can imagine it, we can build it, here at our factory headquarters in Austin, Texas.

Formaspace can help get your aerospace projects off the ground.

Our customers include some of the leading names in the aerospace industry, including Boeing, NASA, and SpaceX. And more than 350 colleges and universities have chosen Formaspace furniture for their student labs, classroom facilities, and more.

Find out why Formaspace’s industrial-strength, American-made furniture leads the industry.

Contact your Formaspace Design Consultant today.