There’s a quiet revolution underway in laboratory science. Today’s researchers are discovering new ways to create rare minerals, replacement biological organs, and food for human consumption (such as meat and dairy) in a laboratory setting. Let’s take a look at the scope of these new emerging technologies and the impact they will have on the laboratory market — and on our lives in the future.

Man-Made Diamonds that Rival the Real Thing

Let’s start with a simple yet instructive example.

Synthetic diamonds have been grown in the laboratory since the mid-1950s using a technique called chemical vapor deposition (CVD), which grows a larger diamond from a very small natural diamond “seed.”

Until recently, however, synthetic diamonds, with their telltale yellow tint, did not pose a threat to the natural, gem-quality diamond market (think wedding rings, necklaces, etc.). But the newest generations of colorless lab-grown diamonds are difficult to distinguish with the naked eye from “real” natural specimens. They will be slightly cheaper to produce than mined diamonds, but the high electricity costs involved keep the prices fairly close – manufactured diamonds are estimated to cost $343 per carat versus $367 per carat for mined diamonds.)

The market impact? According to a report from Morgan Stanley, lab-grown gem-quality melee diamonds (less than 1/2 carat) could capture 15% of the $14 billion market, while larger diamonds could take a 7.5% share by 2020.

It’s Alive! Primitive Artificial Brains, Biological Organs, and Chemicals Created in the Laboratory

Healthcare is another area where laboratories are expanding beyond their traditional roles of providing scientific research and clinical testing. We are entering a brave new world where laboratories are producing synthetic organs and other biological components directly.

Embryonic Brain Organoids

Can we create a living artificial brain in the lab?

Not just yet, but the latest advances at places like Case Western Reserve University School of Medicine, Rockefeller University and Cambridge University in the UK indicate great progress in creating what are known as embryonic organoids*.

*Organoids are three-dimensional, lab-grown cell clusters that mimic natural organs or tissues.

Compared to the fully developed human brain, which has around 80 – 90 billion neurons, these lab-grown organoids only have around two million functioning neurons (making them similar to a cockroach, zebrafish, or the brain of a 12 or 13-week fetus). Yet, even with these limited capabilities, lab researchers have found lab-cultivated organoids capable of developing tendrils on their own to physically reach out and connect to nearby spinal cord and muscle tissues.

What’s the benefit? Artificial brain organisms created in the lab will provide new opportunities for researching disease treatments, from Alzheimer’s to Parkinson’s — and beyond.

Artificial Blood Vessels Created in the Lab

Along with cancer, cardiovascular disease is one of the causes of morbidity in North America. Researchers at the University of British Columbia recently announced the successful creation of a laboratory-created vascular blood system organoid; it was specifically designed to mimic the damage caused to blood cells by diabetes in order to test new clinical treatments.

Formaspace created five new laboratory installations for a leading medical device manufacturer known for inventing the world’s smallest FDA approved heart pump.

Laboratory-Grown Organs, Bone, Hair, and Gut Flora

These are not the only organs in the body that are being replicated in the laboratory.

Uterine Transplants

Scientists from Tel Aviv University and Ichilov Hospital in Tel Aviv, Israel have grown new tissue in the laboratory that mimics the structure and activity of the uterus. It’s hoped one day than women in need of a replacement uterus (whether due to genetics or disease, such as cervical cancer) will be able to have children after a successful artificial uterine transplant.

Laboratory-Grown Human Bone

Meanwhile, researchers at the University of Massachusetts Lowell have developed a new technique for growing human bone in the laboratory. By adding microparticles derived from chicken eggshells to a hydrogel matrix, UML scientists were able to create stronger, laboratory-cultivated bone structures for bone grafts and other surgical procedures.

Researchers hope that the new lab-grown bones will replace the need to ‘harvest’ bones from the patient’s own body, a procedure that is commonly used today.

Lab-Cultivated Hair Follicle Replacement

Laboratory-gown hair follicles are another new breakthrough which could treat male-pattern baldness as well as hair loss by women.

(Due to birth defect concerns, pregnant women cannot come in contact with Rogaine, a common topical treatment for baldness.)

The new method for growing hair in the laboratory is quite ingenious. First, human skin is grown around a unique 3D printed plastic mold that’s kitted out with micro-sized (0.5 mm) extensions. Hair follicle cells are then transplanted onto mold, which acts as a scaffold to guide the growth of the new hair. A new chemical cocktail (which inhibits a pathway known as JAK-STAT) is applied to the hairs cells to encourage them to grow.

Gut Flora

We’ve all become more aware of the important role that our gut flora has on our health. (Some researchers call it our “second brain.”)

Researchers at Washington University School of Medicine in St. Louis collaborated with Thaddeus S. Stappenbeck, MD, PhD, the Conan Professor of Laboratory and Genomic Medicine, to create cultured intestinal stem cells.

The result, known as “mini-guts” in a petri dish, incorporates all the cell types and structural complexity of a real intestine. This allowed them to grow the most common type of Cryptosporidium parasite in the lab in the realistic “mini-gut” environment — something that hasn’t been possible to do before now.

The creation of realistic “gut” models in the laboratory will help speed up research into the complex interactions taking place in our intestines, and may soon lead to new gut treatments created in the lab that can be introduced into patient’s intestines and colons, potentially reducing the current need for “donor” fecal transplants.

Synthetic Chemical and Drug Compounds Made in the Laboratory

Get ready for another revolution in artificially manufactured chemical and drug compounds made in the laboratory.

Artificially-Grown Proteins using New Transgenic Methods

Scientists at Cornell University and the University of Illinois, Urbana-Champaign, are investigating new ways to produce proteins used in pharmaceuticals, enzymes for consumer goods and industrial applications, and the nutritional value of foods and feed products.

Rather than relying on current cell-based methods, which use mammalian, insect, fungal, or bacterial cell cultures as protein factories, the researchers are evaluating the use of transgenic tobacco plants (at commercial scale) to address what they expect to be a $300 billion global market for recombinant proteins for pharmaceutical and industrial applications.

Initial tests of chloroplast-engineered tobacco plants were able to produce significant quantities of bacterial protein Cel6A (an industrially-valuable cellulase used in manufacturing detergents, textiles, and animal feed processing) so the new method could lead to more cost-effective and safer production compared to current methods.

Laboratory Synthesis of Marijuana Chemical Compounds (THC and CBD)

We’ve written before about the rapidly growing demand for cannabis (marijuana) testing laboratories, due to the changing rules governing marijuana use across the USA.

The market for field-grown marijuana might be turned upside down now that scientists at UC Berkeley have been able to create two of the most important active ingredients found in cannabis — THC (tetrahydrocannabinol) and CBD (cannabidiol) — in the laboratory using a genetically-engineered yeast.

THC is the chemical that gives users the marijuana “high” while CBD has emerged as a therapeutic drug treatment that, among other uses, helps juvenile patients afflicted with childhood epilepsy syndromes, such as Dravet syndrome and Lennox-Gastaut syndrome (LGS), better control their seizure episodes.

Laboratory Manufactured Food and Agriculture Products

Synthetic, laboratory-grown food may have the biggest impact of all.

Concerns about climate change, sustainability, and cost are encouraging startup companies to investigate laboratory-based methods for producing enough food to feed the planet — before it’s too late.

Let’s look at some of the latest developments.

Edible Fish Grown in the Laboratory

Concerns about the health of the world’s oceans — and the seafood stocks upon which we depend upon for food — are rising due to a range of factors, including overfishing, increased water temperatures and ocean acidification (which destroys calcium-based shellfish shells), coral bleaching, and widespread ingestion of microplastic particles by sea creatures up and down the food chain.

What to do?

As a consumer, you may have noticed Good Catch Tuna on the shelves of Whole Foods Market*. It’s a tuna substitute, made from 6 six different plant-based ingredients, much like plant-based hamburgers and the like.

(Disclaimer: Whole Foods is a subsidiary of Amazon, a Formaspace client.)

However, other food laboratory companies, such as San Francisco-based Wild Type, are investigating how to grow actual fish fillets — in this case, salmon ones — in the laboratory using cellular agriculture technology. They recently held a tasting in Portland, Oregon, serving Hawaiian poke and sushi rolls made of the salmon created in the lab. Scaling up production is part of the problem — at present, it took Wild Type three full weeks to “make” the salmon they served at the tasting.

“Real” Meat Products — Developed in the Laboratory

Wild Type has some stiff competition from Impossible Foods, the fast-growing laboratory food company (it plans to expand its R&D staff to 200 people by the end of this year).

We first mentioned Impossible Foods earlier this year in a review of food testing laboratories. As a quick recap, Impossible Foods has developed a beef substitute for hamburgers (available at Burger King) that retains the quintessential taste and texture of meat by incorporating heme, an iron-rich protein, into the recipe.

Part of Impossible Foods’ new mission is to create a lab-based food substitute for each of the major animal-based foods on the market.

Lab Made Milk and Cheese Substitutes

New competitors are emerging in the milk and dairy sector, thanks to the development of synthetic whey made in the laboratory.

Whey is a critical protein component used to make a huge variety of products, from protein shakes and energy bars to yogurts and cheese.

It’s also a big business. (US whey exports last year totaled $10 billion.)

Like Impossible Foods, Perfect Day is a San-Francisco-based laboratory food startup; that wants to create dairy products with the taste of real cheese and dairy — but made with non-animal protein. Perfect Day has researched how to create custom yeast and bacteria to grow proteins that taste, for example, like real dairy milk.

There are two other laboratory food startups in the market as well. New Culture is researching manufacturing cheese products, including mozzarella, from lab-grown casein proteins. Meanwhile, Motif Ingredients has $90 million in investments to develop lab-grown dairy proteins flavor and texture ingredients.

As an aside, what happens when we have fewer cows? Well, environmentalists would argue that’s good for the planet, but there won’t be as much ‘raw material’ for leather goods. Not to worry… the New Jersey-based startup Modern Meadow has created lab-grown bio-leather products using genetically engineered yeast.

Insect-Based Foods Processed in the Laboratory

What about one of the biggest natural sources of protein of all? — insects.

Does the thought of eating “bugs” make you squeamish? (That’s not the case in all cultures, where eating insects may be a common practice.)

Researchers concerned about sustainability have proposed focusing efforts on lab-grown insect meat. In this scenario, the insects would feed on plants but would be genetically modified to produce “meat” products that grow quickly, provide sound nutrition, and have good flavor.

According to Natalie Rubio, a researcher writing in Frontiers in Sustainable Food Systems, “compared to cultured mammalian, avian and other vertebrate cells, insect cell cultures require fewer resources and less energy-intensive environmental control, as they have lower glucose requirements and can thrive in a wider range of temperature, pH, oxygen, and osmolarity conditions.”

Bon appetit!

Laboratory-Grown Materials and Foodstuffs in Space

If the thought of insect-based foods wants to make you look for another planet to live on, let’s consider some of the materials and food items you’ll need to get there.

The European Space Agency is looking at ways to help astronauts in space suffering from long term deterioration of their bone structures.

The solution is on-board “printing;” printing replacement artificial skin and bones – using bio-plasma as the “ink.”

Indeed, that’s not the only 3D printing solution under consideration for space travel.

NASA has recently awarded a $74 million contract to Made in Space, a company that is developing spacecraft-based 3D printing equipment to build the largest structures needed in low-Earth orbit, rather than sending them into space directly from Earth. The first application will be to print out two 32-foot beams in space, which will hold massive solar panels capable producing nearly 500% more power than conventional earth built solar panels.

Having enough food to eat in space is another critical issue. NASA has been experimenting with ways to grow foodstuffs on the International Space Station (ISS) — growing hot peppers in the ISS laboratory is their latest agricultural experiment.

We can only guess if it’s more flavorful than powered Tang.

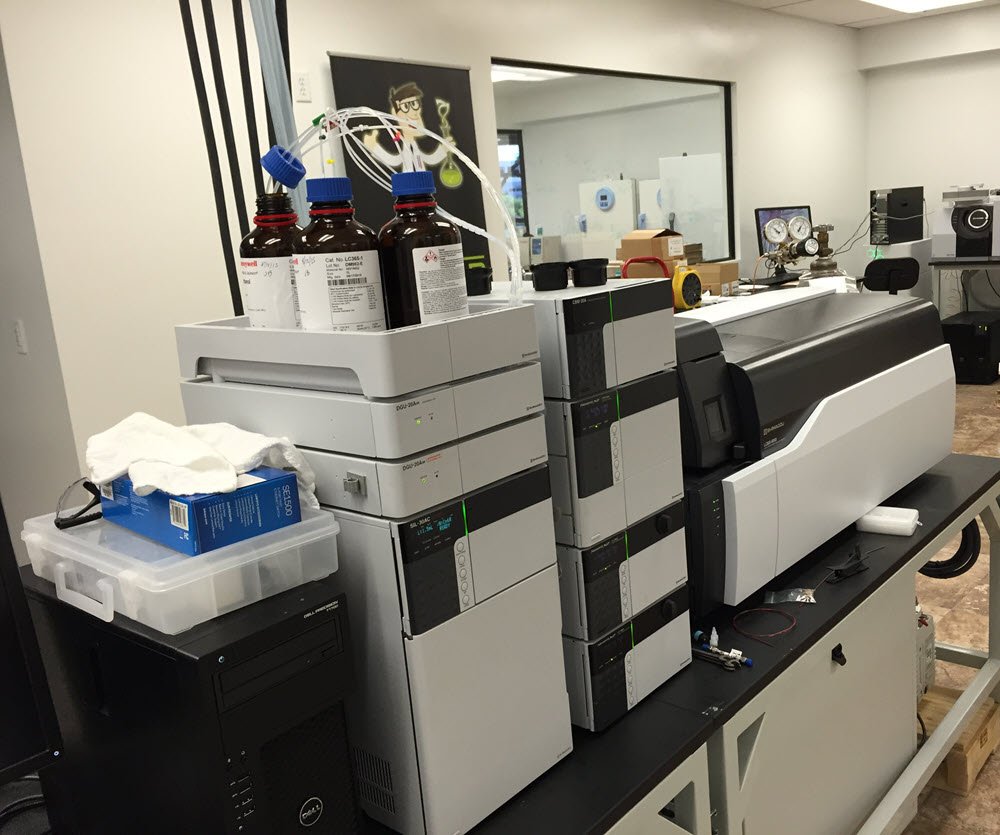

Formaspace is Your Laboratory Partner

Formaspace wants to be your laboratory partner. Whether you are building a new laboratory or renovating an existing facility, we can assist in the design process and then build your custom lab furniture here at our factory headquarters in Austin, Texas.

If you can imagine it, we can build it.

As a GSA Schedule Supplier, Formaspace has helped our laboratory clients build out their laboratories across the full spectrum of government, military, and commercial entities, including well-known companies, such as Roche, Schlumberger, and Antech Diagnostics.

We’re ready to help you next.

Whether you are designing a new facility or renovating an existing laboratory, our Formaspace Design Consultants have years of experience helping lab managers and architects to create state-of-the-art laboratory facilities.

Take advantage of our expertise. Contact your Formaspace Design Consultant today.