We first introduced you to Keith Moynihan, our new CFO, when we welcomed aboard many of the new faces that recently joined the Formaspace family. As you may recall, Keith, who hails from Massachusetts, is an avid runner, has been married for 31 years, and is the proud father of three sons, now 17, 23, and 25 years old.

Formaspace lab and industrial customers will be interested to learn about your background, especially your experience working at brand name, research-driven manufacturing companies. Can you give us a brief overview?

Thank you. I’m a 30-year financial executive that has worked for a number of well-known Fortune 500 companies in my career, including GE, Dover, Newell Rubbermaid, and International Paper.

My core financial experience has been working for public manufacturing companies, where I’ve worked closely with the executive management teams to drive continuous improvement, implement sound financial controls, and increase profitability.

I have also participated, and in many cases, drove major elements of a number of business mergers, acquisitions, divestitures, and restructuring events across many of the companies I have worked for.

Formaspace not only manufactures its products in the USA, we’re also big advocates of promoting a renaissance in American-manufacturing. What’s your take on the US economy overall, and are you optimistic about the opportunity of bringing more manufacturing back to the USA?

In 2019, the US economy grew 2.1% over 2018 — admittedly, it’s on the low side, but nonetheless, it represents positive growth.

However, over the past 5 – 10 years, we’ve continued to see some significant amounts of manufacturing shift to China — and other lower-cost labor markets — which has had a negative economic impact on many parts of the US. The technology shift around AI (artificial intelligence) and automation is changing the workforce dynamic in many industries.

I think we’ll see companies bringing more of their manufacturing back to the US in the coming years as things shift due to technology. The fast-changing workplace means businesses and policymakers face important choices. Adapting to a new workforce composition in the face of rapid technological change is challenging, as workers’ productivity and capacity to transition into different occupations will depend on their ability to develop new skills. Education and on-the-job training should be a priority, enabling businesses and workers to boost their productivity, which will, in turn, help workers to retain good-quality jobs and boost wage growth. I feel that the US is blessed to have a wide range of multi-skilled labor, and as companies balance technology, productivity, and profitability, America is an attractive place to be.

We understand you are quite bullish on the furniture manufacturing sector in particular. Tell us more.

My view of the furniture industry is that it’s a strong, growing industry-aligned closely with the vast construction that is going on throughout the country and world.

According to the five-year forecast estimates I’ve been reading, this industry is looking at CAGR growth rates ranging from 5 – 8%, which are extremely attractive.

With the tremendous growth in construction, combined with the trend toward companies remodeling — to create more inviting, modern workspaces — I think this industry will do quite well in the coming years.

Any specific thoughts about the positioning of Formaspace in the furniture industry sector?

One thing that stands out to me is customization. I believe that one of Formaspace’s key strategic advantages is its ability to offer customized products for its customers, even in large quantities.

The way I see it, it’s a trend for the future.

I watch how my 17 and 23-year-old sons always want something that’s unique and different from what the others have, whether it’s a car color, a unique pair of shoes, or clothing purchases — the younger generations coming up are clearly attracted to custom choices, and the customers that are buying furniture are no different.

I’m also excited to be coming to Formaspace at a time when revenue growth projections are in the double digits

Indeed, I believe the major challenges we will face will be in-house, specifically, how we keep up with and manage our growth.

But the good news is we have smart people on board who are striving for operational excellence.

Can you elaborate more about your philosophy on achieving operational excellence?

In my view, manufacturing companies are inevitably faced with challenges.

What distinguishes the good companies is that they are both observant and proactive.

They stay aware of the risks and circumstances that could potentially impact their businesses and react accordingly.

They also continuously review their strategies and objectives, to create effective countermeasures in advance to ensure that their goals and financial objectives are met.

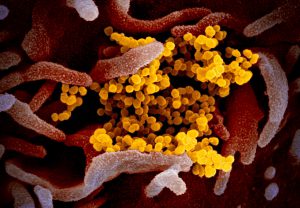

The current coronavirus outbreak would be a good example of an operational challenge for many American manufacturing companies. What are your thoughts on this?

Yes, the coronavirus is a significant example of a challenge that has arisen without much advance warning, although the threat of a pandemic has been on the horizon since the previous SARS, MERS, and Ebola outbreaks.

In the short term, this outbreak is going to be especially problematic for American companies that are heavily reliant on imported goods and materials manufactured in China.

Fortunately for us, Formaspace sources nearly all its raw materials, including steel, here in the USA.

But for those companies with a heavy reliance on goods from China, it’s not good news to hear about significant disruptions to supply chains caused by Chinese factories shutting down in an attempt to slow the virus outbreak.

As I mentioned earlier, Chinese labor and production costs have been rising relative to our costs here at home, and when you add in the challenge of production disruptions caused by this virus outbreak, it might convince more companies to think about making strategic changes in their business operations and bring more of their manufacturing back to the USA.

That said, the overall situation is changing rapidly, and the full world-wide impact is still unclear — both overseas and here at home.

And, since I’m more of an economist and definitely not an epidemiologist, I’ll limit my comments to the economic and operational issues. From an operational perspective, that means we plan for the worst and hope for the best.

Putting the coronavirus issues aside, what are some of the other operational challenges you see in the furniture manufacturing space?

In our industry, quality, creativity, and speed are very important, and they are three attributes that any good manufacturer needs to excel at. If you can excel in those areas, you will have repeat customers, and you will drive a very successful business.

During my career, I’ve also learned that the ‘great’ companies employ a ‘continuous improvement’ mentality — by that, I mean encouraging Lean and Six Sigma type thinking. Companies that implement these methods end up driving better profitability than those who do not.

For manufacturing companies, the largest expenses are normally materials, labor, and overhead required to make products.

Tracking inventory accurately is especially crucial because inventory is typically a manufacturing company’s largest asset (and cash outlay). You need to have the right inventory at the right time — but no more than necessary!

Having an efficient operation on the manufacturing floor or in your admin functions — with sound, streamlined, and well-understood processes — will yield the best margins and lowest cost, which translates to more money going to the bottom line.

You make it sound so easy!

Sorry, I don’t mean to mislead you. The reality is it’s not easy to drive change.

Establishing sound processes that involve people and systems is quite challenging.

You need a good understanding of what the company’s current processes are first before you can move on to identify what needs to be changed in order to achieve your specific goals.

It’s hard work to analyze each step of an existing process, especially if you use the “5 Why’s” approach from Lean manufacturing principles.

But I believe these are the necessary steps required to achieve the future “to be” state that’s needed to achieve a company’s operational goals.

This approach is not limited to the enterprise level.

I feel that in every job, there are better and more efficient ways to do things, and every idea counts.

My personal view is that all of us should take 5 or 10 minutes out of our day to ask ‘what can I do better than I did yesterday?’ and then make one change each day to improve something.

Maybe this is a good time to give us some insights into your overall management approach and philosophy.

I hope my leadership and guidance, built over many years of experience, will add value and help keep Formaspace growing as a profitable company.

Like all fast-growing companies, we face many challenges, but fortunately, we have a group of talented people that want to overcome those challenges.

When it comes to management philosophy, I’d characterize my management style as one of inclusiveness, one that’s focused on getting the team to act as one.

The difference between the power of many minds working toward a common goal versus one person working alone is huge.

But team members also need to listen and communicate effectively in order to learn from each other. They need to hold each other accountable for hitting goals and objectives that they set.

Tell us more about your approach to Team Building. Many companies find this challenging. Are you drawing on your background as an athlete here?

Team Building is something that great companies are really good at.

And yes, I’m drawing on my experience from athletics.

When you look at successful sports teams that win, the majority of the time, what distinguishes them is they have a strong team spirit and bond.

They all know and respect each other. They are willing to push hard for each other and work together to achieve the greater goal of the team winning.

A good first step in creating a successful team across the whole organization is for the top management to demonstrate visible respect and support for each other.

In practice, creating a team can be hard to do because of the different types of personalities of each team member as well as each of their life situations.

I can give you a good example.

I’ve had the pleasure to work in a high-performance work team environment (at a Proctor and Gamble company) that produced adult incontinence products.

They invested in a rigorous training program for their employees that rotated them through a multi-functional curriculum; paid them really well; and empowered them to not only hit their production goals but also make all of the buying and spending decisions on all things related to the product.

This team had the responsibility to fix anything on the production line, including machines that broke (relying on their extensive training); they also had to buy raw materials; make scheduling decisions, and much more. They worked together, took breaks together, and regularly participated in off-site company events together — they were a true team.

Their results were incredible. Whatever goals management set, they hit.

I would call out two keys to their overall success.

First was the respect and support they had for each other.

And second was the accountability they were given, which drove them to feel the need to hit their goals as a team.

Thanks for sharing that story, that’s a great recipe for success. But we have another related challenge we’d like to touch on. We keep seeing statistics that many US manufacturing companies find it difficult to recruit enough skilled workers. What are your thoughts on this?

Companies today do find it challenging to find good people who enjoy working and love what they do and have a willingness to help the company grow.

Recruiting talent today is also made more difficult because of an emerging “generation gap,” one that seems to be rooted in a mismatch of expectations. In many cases, the younger generations in the job applicant pool have what might be called an entitlement mentality; in other words, they are looking for rewards and promotion at a faster pace than their ability to increase their knowledge and contributions to the company would merit.

And for manufacturing companies, it’s becoming very tough to match the pool of available applicants with the skill sets needed for job openings in the traditional trades.

Having said that, companies that are creative in creating a welcoming, team-oriented work environment, who offer good benefits (working from home, for example), and provide job flexibility, while holding folks accountable to an agreed job role with tangible metrics, will do well.

Thank you, Keith, for taking the time to speak with us today. Do you have any closing thoughts about what we can expect from Formaspace in 2020?

Of course, and thank you for the opportunity.

Regarding 2020, I think it’s going to be a good year for Formaspace.

We are making some very big investments to grow the business.

As you know, over the last three years, we’ve expanded beyond our traditional laboratory and industrial furniture business to take on the broader commercial interior furniture market.

That side of the business has really gotten traction as a supplier of custom furniture, and we’ve recently landed some very high profile projects — unfortunately, I can’t talk about them yet because we are under an NDA.

But what I can say — because we have made these announcements public — is we are investing in a new brand for this side of the business, called Formaspace Contract. We think this new branding does a better job addressing the wider market for commercial interiors. After all, it’s clear to all of us that the nature of work is changing by becoming more mobile; it’s no longer centered on working in traditional office desk settings as it was in the past.

Another investment we are making is building out a new permanent furniture showroom on the 11th floor of the Chicago Merchandise Mart. And we’re excited to launch it in time for this year’s NeoCon contract furniture expo.

It marks the first time we’ve expanded our permanent real estate footprint beyond our factory headquarters here in Austin, Texas.

And it’s really an investment for our dealers and partners who have been asking for a bigger Formaspace presence at NeoCon. Now we will have a place for our dealers to bring to clients — to see, touch, and feel Formaspace Contract custom furniture products first hand – throughout the year.

That’s very exciting news! Thank you, Keith Moynihan, for your time.