Are you looking to improve the academic achievement of your K-12 STEM education programs? Do you want to increase student engagement, boost test scores, and inspire more creative thinking at the same time? The solution you are looking for may be a Makerspace located in your campus library — one that encourages hands-on, activity-based learning – that helps students apply what they’ve learned in the classroom to their own personal projects. We take a look at some of the best practices fReador adding a Makerspace to your K-12 library, with tips and tricks that apply to budget-conscious projects as well as full-scale, dedicated facilities alike.

The Makerspace Transformation Opportunity for School Libraries

Leading educators are turning to Makerspaces to improve learning outcomes in STEM (Science, Technology, Engineering, and Math) programs.

Why? Makerspaces help encourage self-discovery, independent experimentation, and hands-on problem solving among students.

And libraries play a special role in the adoption of Makerspaces, particularly in higher education. According to a recent American Society for Engineering Education (ASEE) survey, libraries are the most common host location for Makerspaces on college and university campuses.

Why libraries? There are several factors at work. First, the traditional role of libraries is in transition, with many hardcopy reference books and periodicals being removed in favor of online resources, which frees up valuable space for other uses. Second, libraries have longstanding expertise in acquiring and managing assets (including skills in budgeting, grant writing, inventory control, etc.) and sharing them equitably with their community.

Members of the American Library Association share their experiences in adding Makerspaces within their institutions.

Makerspace Learning: What Can Your Students Do in a Makerspace?

Here are just a few of the many types of projects K-12 students can pursue in a Makerspace:

Design and Construction of Useful Objects, such as Product Prototypes

Makerspaces offer K-12 students an opportunity to create useful, aesthetic objects driven by their own unique imagination. Younger students can, for example, build 3D objects from soft, color modeling clay (which hardens in a toaster oven) while advanced secondary students can tackle projects ranging from furniture design to using 3D CAD computer software and printing out 3D models.

Makerspace Learning Skills at Work:

Problem-solving, sketching, design visualization and conceptualization, sculpting, graphic design, industrial/product design, 3D scanning, 3D CAD design, 3D printing, CNC machining, woodworking, model making, plastic and metalworking.

Authoring Immersive AR/VR Games and Applications, as well as Video Productions, Presentations, and Training Materials

Many believe that today’s emerging immersive AR/VR-based game applications are laying the groundwork for tomorrow’s Hollywood entertainment blockbusters — as well as raising a new standard for training applications and communications presentations throughout Corporate America. Makerspace studio spaces allow K-12 students to learn these new technologies, from young students creating new Minecraft levels to older students using professional game authoring environments, such as the Unity game engine.

Makerspace Learning Skills at Work:

Storytelling, storyboarding, scriptwriting, green screen cinematography, video and film editing, presentation communication skills, interactive AR/VR game authoring and programming.

Creating Printed Materials, Fabric and Soft Textile-based Designs, including Clothing and Fashion Accessories

Creating Printed Materials, Fabric and Soft Textile-based Designs, including Clothing and Fashion Accessories

Many of today’s students are motivated to learn about fashion clothing design, quilting, and other textile-based applications. Print technology, whether paper-based lithography or textile graphics, can also engage students while teaching them important design and visualization skills. Taken together, these skills can be applied to future careers, from garment manufacturing to printed circuit design, to advances in wearable technologies.

Makerspace Learning Skills at Work:

Sketching and visualization skills, graphic design, print technology, laser cutting, quilting and sewing skills, fashion clothing and accessories design, textile design and technology, inflatable and pneumatic design, upholstery design.

Developing Interactive Electronic Devices, including Internet of Things Applications

New low-cost electronic devices, such as the Arduino, Lego Mindstorms, Raspberry Pi, were designed with teaching students in mind. Makerspaces kitted out for experimentation in electronics can help K-12 students develop valuable skills in programming electronic devices, as well as integrating them into Internet-capable devices (Internet of Things), from fighting robots to wearable devices.

Makerspace Learning Skills at Work:

Computer programming, problem-solving, electronics integration, circuit design and logic programming (incl. Arduino, Lego Mindstorms, Raspberry Pi), custom electronics prototyping (soldering, breadboards, etc.)

Formaspace created the custom furniture used in the “Create at Arizona Science Center” Makerspace.

Design Considerations for Successful Makerspace Projects

Ready to get started?

Great. Let’s start with some of the key foundational principles that will help make your Makerspace project successful.

1. Safety is a Primary Design Consideration

Most accidents are preventable — in retrospect. Careful design planning can help you avoid many common types of accidents entirely. For example, much of the equipment in Makerspaces can be considered dangerous if precautions, such as Personal Protective Equipment (PPE) are not taken. It’s also important to avoid choosing furniture that’s not designed to support heavy equipment and materials (Formaspace steel-welded tables and chairs can handle a minimum of 1,000 pounds.) Make sure every piece of equipment and all working materials can be stored away neatly to prevent tripping hazards from excess clutter; this includes specifying overhead power supplies to prevent tripping hazards due to extension cables running along the floor.

2. Durability Means Longer Service Life

You want to make your investment dollars go further, longer. Makerspace facilities can see extra-heavy-duty use compared to normal classroom or office environments. That’s why it’s important to choose industrial strength products, such as Formaspace furniture. We build our furniture out of heavy-duty steel then powder coat it for years of service. And we offer a no-questions-asked guarantee that protects your investment for a full twelve years of round the clock use.

3. Flexibility Helps Future Proof Your Investment

Changing requirements are a headache for facility planners and campus architects. But what if your wall systems and furniture installations were easy to update, upgrade, and reconfigure — with simple hand tools. Modular furniture solutions from Formaspace are the answer. We offer a wide range of solutions, starting with demountable wall systems and partition dividers (that can hide utility cables for electricity, networking, and more) that can be changed easily as your needs change. The story is the same for our furniture systems, including workbenches, desking, and benching systems — all of these can be reconfigured to help future proof your investment. Because we make all our furniture here in our Austin, Texas factory, we can supply you with matching components years from now — no planned obsolescence here.

4. Ergonomics Ensure Health and Wellbeing of Teachers and Students

As a major American manufacturer of educational furniture for classroom laboratories, libraries, conference rooms, cafeterias, art studio spaces, makerspaces, and more, Formaspace knows that growing students come in different sizes. That’s why we specialize in height-adjustable furniture than can be raised or lowered to fit students of different ages. We also offer ergonomic seating options, as well as easy-touch computer monitor mounts that make it easy for students to sit properly in ergonomically correct positions.

5. Partner with a GSA Schedule Suppliers That Can Meet Your Needs

Finally, it’s important to partner with an American furniture manufacturing company that has experience in the education market. Formaspace is a GSA Schedule Supplier with more than 350 college and university clients, including most of the Ivy League institutions, plus countless primary and secondary customers.

Sample Makerspace Transformation Project Plans

Let’s look at two Makerspace project plan examples:

Budget Conscious Makerspace Plan

Mobile Carts

Strong steel mobile carts from Formaspace can maximize flexibility while helping to keep your student projects organized and tidy throughout the day. When the session is over, simply roll the carts into storage to recover the use of your floor space for other activities.

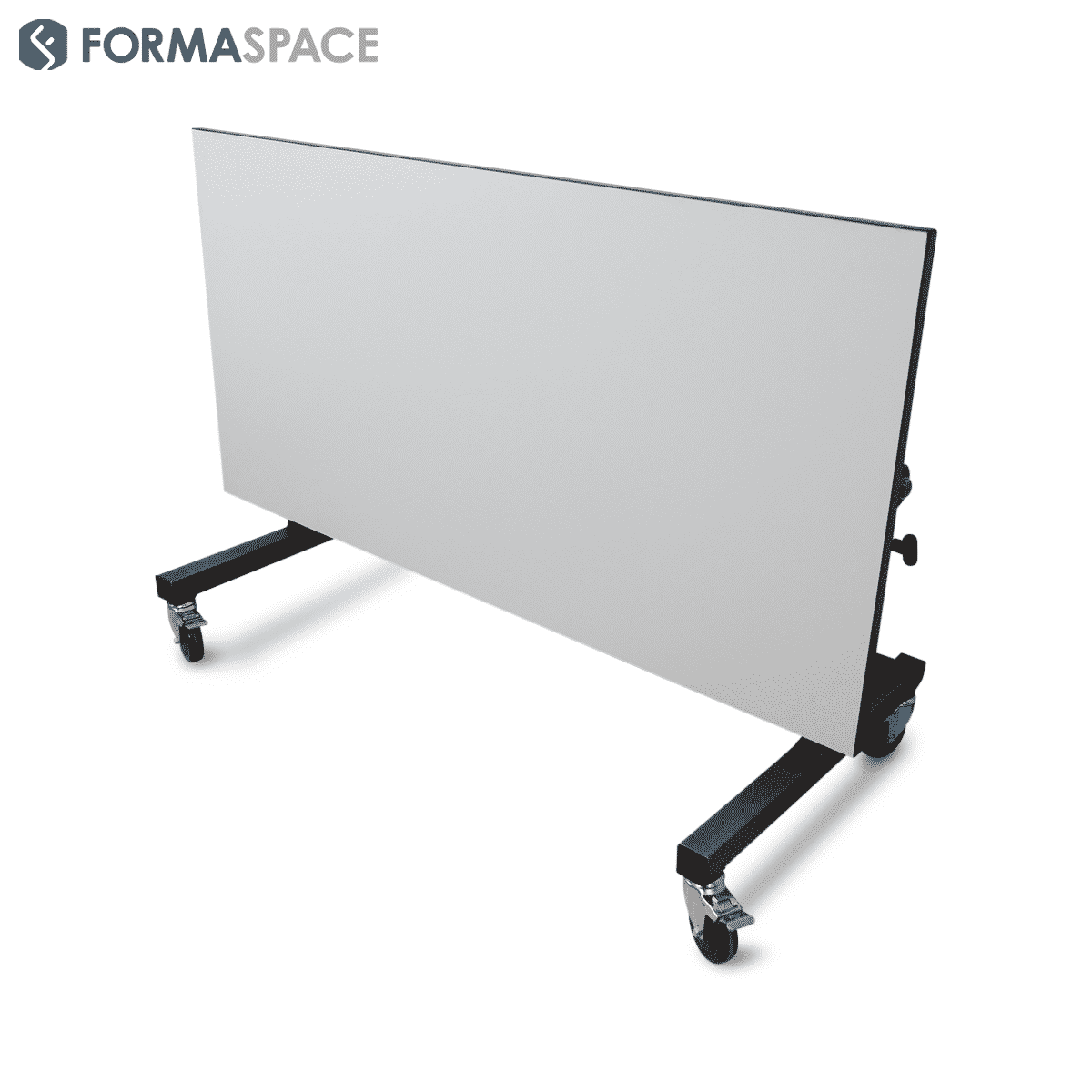

Mobile Dry Erase Boards Partitions

Mobile partitions with built-in dry erase boards not only help students and teachers communicate ideas, they can also serve as mobile space dividers that help segregate different groups of students and projects from one another.

Fold-Up Work Tables That Convert into Gallery Panels

Formaspace offers unique worktables that can fold up for more compact storage against the wall or in a storage closet, freeing up valuable space when not in use. These tables can also serve as gallery panels to showcase student projects.

Workstations with Storage

The more storage available in a Makerspace, the better. Formaspace offers a wide range of custom workstations with built-in storage — below and above the worksurface — to maximize your available floor space. (We also offer ESD worksurfaces for electronics projects; these prevent accidental damage to electronics projects due to inadvertent static electric shocks.)

Full-Scale Makespace Project Plan

If you have the budget for a major remodel or purpose-built Makerspace project, there are even options available to make your new facility even more productive and valuable to the students and faculty at your K-12 institution.

Here are some ideas to consider:

Dedicated Storage for Equipment, Materials, and Student Projects

Consider adding dedicated storage for equipment, such as a lockable tool crib that would allow staff to ‘check out’ tools to students. Some makerspaces keep their materials (some of which are not-inexpensive) in lockable ‘materials zones’ as well to allocate resources fairly. Finally, consider creating dedicated storage areas for individual student projects that are ‘in-process.’ This will reduce clutter and ensure the common areas are available for all to use.

Custom Zones for Specific Applications

More ambitious Makerspaces are often divided into different zones based on the tools and types of projects. For example, it makes sense to segregate woodworking tools (which require dust control and ear protection) in a ‘zone’ that’s separate from other activities, such as clothing design or printmaking.

Overhead Utilities, Fume Control, and Wash-up Stations

Some activities undertaken in Makerspaces require students to clean up after class. It’s important to provide wash-up stations (which can double as emergency eye-wash stations). Some processes, such as soldering, may create noxious fumes, so a fume hood may be warranted in some cases. Adding this kind of infrastructure can get complicated in existing facilities, but Formaspace offers special solutions that make adding things such as wet sinks easy: our all-in-one wet sinks use overhead utilities to simplify installation and maintenance.

Custom Furniture Solutions to Meet Your Exact Needs

If you can imagine it, we can build it for you at our factory headquarters in Austin, Texas. Because every educational facility is different, we specialize in working with you to come up with unique, custom solutions that will make your Makerspace project a success.

Formaspace is Your Makerspace Transformation Partner

Formaspace has long experience in supplying furniture for Makerspaces, including recent projects at Arizona State University and Seattle University.

Whether you are an education professional, librarian, architect, or builder, we want to share our expertise with you to make your Makerspace project a success.

Contact one of our friendly Formaspace Design Consultants today.

Creating Printed Materials, Fabric and Soft Textile-based Designs, including Clothing and Fashion Accessories

Creating Printed Materials, Fabric and Soft Textile-based Designs, including Clothing and Fashion Accessories