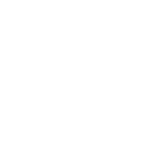

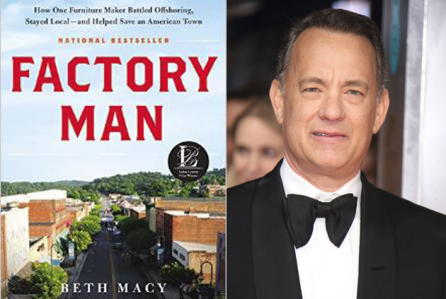

As much as we love the business of making technical furniture, we really never would have believed that a book on furniture manufacturing would make the New York Times bestseller list. But the fact is that author Beth Macy tells a fascinating tale. The story is so compelling that, according to Macy’s website, Oscar-winning actor Tom Hanks has signed up to be executive producer of an upcoming HBO miniseries currently in development, based on the Factory Man book.

Why Would Furniture Manufacturing Catch the Attention of the Reading Public this Year?

(Spoiler alert: we plan to touch on some of the book’s storyline in the following paragraphs so be forewarned!)

At its heart, Factory Man has all the characteristics of a biblical tale, Shakespearean play or Greek tragedy. A family patriarch rises up from modest means in a remote area of Appalachia to achieve unimagined financial success, creating an industry dynasty and regional economic powerhouse in the process. Successive generations of sons lead this business through a postwar boom, growing the business to near Fortune 500 status. Along the way, a daughter wrests control of the business empire in favor of her husband as her father lies on his deathbed.

The son — who was once destined to inherent the helm of the company — is spurned and humiliated by his brother-in-law at every turn. Humbled, the son moves away from the company town he grew up in to make a fresh start in a new city — by trying to resuscitate a moribund factory that’s up against the ropes. While the brother-in-law chases the dream of achieving Fortune 500 status and flies the company’s corporate jet to attend dozens of corporate board meetings, he fails to aggressively react to new competitive threats from abroad, which in the coming years will bring his furniture empire to its knees. Not so the son who moved away.

He’s quick to pick up on the threat and make a stand. He resists immense pressure from fellow domestic furniture competitors calling for him to throw in the towel and accept that the time for manufacturing in America has passed. Undeterred, the son takes on his foreign competitors — taking the fight all the way to Washington. In doing so, he saves his factory and his adopted town, while the company town where he was born lost all of its factories, one after another.

John D. Bassett: The Patriarch of American Home Furniture Manufacturing in the 20th Century

It’s a classic tale of family intrigue and reversal of fortune. But whose fortune? Let’s fill in some of the details. The family patriarch is John D. Bassett, who, with his brother Charles, founded Bassett Furniture Company back in 1902. Taking advantage of the magnificent forest resources in rural southwestern Virginia, John D. Bassett built up his furniture manufacturing empire starting with small factory buildings built in front of their farmhouse.

Eventually there would be a John D. Bassett Jr, a John D. Bassett III and a John D. Bassett IV, plus a half-dozen men who married into the family, many of which extended the family enterprise by starting their own furniture manufacturing lines. The names of these related family businesses are quite famous in their own right, including Hooker Furniture, Weaver Mirror, Vaughn Furniture, Vaughan-Bassett Furniture, Stanley Furniture, Polaski Furniture and Lane Furniture. It was the handover from the second-generation to the third that did not go as promised for John D Bassett III, who goes by JBIII. Pushed out from the very company he stood to inherit, JBIII became his own man at the helm of the Vaughan-Bassett Furniture manufacturing company a couple hours down the road in Galax, Virginia.

JBIII: Beth Macy Caught a Real Tiger by the Tail

Author Beth Macy wrote her first feature on JBIII when she was a business writer for The Roanoke Times. Without question, she was trying to catch a tiger by the tail. It’s probably fair to say that members of the Bassett family are very conscious of their historical legacy, and it’s clear that Beth Macy had her work cut out for her in trying to unravel both business secrets and family secrets that had been covered up over many years. But it was worth the effort. The resulting story is one of international intrigue. For example, consider this part of the story: Cognizant of the potential that low-cost imports from Asia could destroy not only his business, but every other domestic furniture manufacturer in the region, JBIII set up an international spy ring to find out exactly what he was up against. His spy-master, a widowed Taiwanese-born translator, succeeded in cracking the core of the case — by locating the source of a mysterious piece of high-quality furniture put on the American wholesale market for the impossibly low price of $100.

In JBIII’s view, this was not only a low price, but an illegal price, for the product was selling in the US for far less than it cost to manufacture — making it a clear case of illegal dumping in JBIII’s eyes. And he was not hesitant to take his case to the Justice Department in Washington and from there to the World Trade Organization, of which China is a member. Amazingly, some of the biggest opposition against bringing the illegal dumping case to the Justice Department came not from Asian importers, but from JBIII’s fellow domestic furniture manufacturers! These seemingly natural allies to the case against illegal dumping had themselves — over time — become more and more dependent on importing Asian goods to sell to their customers — and less and less on manufacturing here at home in the USA.

As it turned out, this unprincipled stance ultimately backfired on many of these very furniture manufacturers who had transformed themselves into furniture importers. Why? It wasn’t too long until their customers, the furniture retailers, wizened up to the fact that they could cut out the factory middleman by sending their own buyers to Asia to import low-priced goods directly, leaving the erstwhile American manufacturers-turned-importers in the lurch and — in many cases — bankrupt. The number of jobs lost in the furniture-belt manufacturing region of Virginia and the Carolinas is quite sobering.

According to Beth Macy’s research, the region surrounding Bassett Furniture once boasted 42,560 jobs, but by 2012, the number had dwindled to only 24,733. The consequences for laid-off workers and their families were devastating. In some towns, the unemployment rate jumped up to between 15% and 20%, one in three families were on food stamp assistance and three out of every four public school students qualified for free or reduced cost lunches. By 2013, Bassett Furniture was down to only 1,500 workers with sales of only $320 million worth of furniture, a figure that was only two thirds of what Bassett sold in its heyday. To survive, the company closed all its hometown furniture factories and is today primarily a retail operation — with Bassett Furniture stores located across the country. It’s also heavily invested in marketing partnerships with cable television channels, such as HGTV.

What is the Moral of This Story?

For good reason, the people of Galax, Virginia take great pride in the fact that JBIII was able to save their core factory and the town. And he won his case against illegal dumping by the Chinese. But there’s a lot more to the story, because trade penalty fines alone were not enough to save the factory. JBIII worked harder than anyone else to revamp, restructure and modernize his furniture factory.

Taking inspiration from Houston’s Jim “Mattress Mac” McIngvale, the largest furniture retailer in the country who’s famous for introducing same-day delivery, JBIII completely upended Vaughan-Bassett’s production, delivery and billing systems. Today Vaughan-Bassett can take an order from a wholesale customer, manufacture and express deliver it within one single week, a process that used to take many weeks, if not months.

The good news is that — on a level playing field — it looks like American manufacturing is here to stay. We find Beth Macy’s “Factory Man” an inspiring story and trust you will too.

Formaspace is Proud to be Part of the Renaissance in American Furniture Manufacturing

Here at Formaspace we’re proud to be part of the renaissance in American furniture manufacturing. We encourage you to join our roster of well-known clients — including Apple, Boeing, Dell, Eli Lilly, Exxon Mobile, Ford, General Electric, Intel, Lockheed Martin, Medtronic, NASA, Novartis, Stanford University and Toyota.

Why not give us a call today at 800.251.1505 to learn more about our full line furniture as well as our furniture consulting and space planning services. We offer a complete line of stock, semi-custom and custom-made furniture, including electronic assembly workbenches, drafting tables, computer workstations, industrial workbenches, lab benches, packing tables and more. All our furniture is Made-in-America right here at our factory headquarters in Austin, Texas. We stand behind our products with the industry’s best guarantee: a full 12 years.