Why it’s Important to Prevent Accidental Exposures and Cross Contamination in the Laboratory

Failure to establish a culture of safety in laboratories handling biospecimens can have real-world consequences — the increased risk of serious laboratory-acquired infections (LAIs).

According to the CDC’s MMWR reports, laboratory workers handling blood products are infected with Hepatitis B at a rate that is 2 to 4 times that of the general population. Lab workers also report higher rates of exposure to Hepatitis C and human immunodeficiency virus (HIV).

According to the CDC, bacteria are responsible for more than 40% of laboratory-acquired infections. More than 37 different bacteria species have been identified as common etiologic agents in the lab — the most common are Brucella species, Shigella species, Salmonella species, Mycobacterium tuberculosis, and Neisseria meningitidis.

If you have not done so already, it’s time to identify a Laboratory Biosafety Officer to help establish an effective safety culture at your facility — and to establish protocols to conform with the relevant CLIA safety regulations 493.1101 (d), 493.1407 (e) (2), and 1445 (e) (2).

Important Resources for Establishing Safer Lab Environments

- Guidelines for Safe Work Practices in Human and Animal Medical Diagnostic Laboratories (Web page, PDF document)

- Biosafety in Microbiological and Biomedical Laboratories (BMBL) 5th Edition (Web page, PDF document)

- World Health Organization (WHO) Laboratory Biosafety Manual – Third Edition (Web page, PDF document) FYI the 4th edition is now in draft. See this video for a discussion of upcoming changes.

Plan Ahead to Avoid Accidental Exposure and Cross Contamination When Working in the Lab

Ensuring the health and safety of lab personnel is of paramount importance.

We take a look at some of the key safety ‘takeaways’ that will keep your staff safer as well as reduce the chance of inadvertent cross-contamination that could imperil the accuracy and reproducibility of your lab experiments and test procedures.

Consider What Can Go Wrong in the Laboratory

According to the CDC, the five most prominent sources of laboratory-acquired infections are:

1. Accidental inoculation by syringe needles or contaminated sharps.

NOTE: Punctures and cuts from so-called sharps, such as needle sticks, broken pipettes, and glass slides, can lead to dangerous Laboratory-Acquired Infections (LAIs). Always have a designated procedure for handling sharps, a place to safely dispose of them, and an appropriate emergency medical protocol to follow immediately after a known or suspected incident.

2. Spills and splashes on the skin or mucous membranes.

NOTE: When it comes to spills, a disorganized workspace or unfamiliarity with handling items while wearing personal protective equipment (PPE) can be just as dangerous as moving too quickly or not paying close attention. Implosion accidents are another risk; these can occur when vacuum flasks or bell jars fail, resulting in sharp debris from broken glass shooting out into laboratory technician’s unprotected eyes, face, or hands. Finally, explosions in the laboratory can be caused by multiple factors, including the mishandling of liquid gases (such as liquid nitrogen, helium or oxygen) in cryogenic containers, or the accidental mixing of incompatible compounds due to handling errors caused by mislabeled or LASA (look-alike, sound-alike) compounds.

3. Ingestion or exposure by mouth pipetting or touching the mouth or eyes with fingers or contaminated objects.

NOTE: Ingestion of chemicals or biological pathogens can occur due to incorrect specimen procedures, such as mouth pipetting, allowing food and beverages in the lab, absentmindedly placing a pen or pencil in the mouth, wearing contact lenses, or using your keyboard or smartphone in the laboratory without a protective cover.

4. Laboratory research activities involving animal bites or scratches.

NOTE: Facilities that handle live test specimens (e.g. vivarium research facilities) should refer to “Section V—Vertebrate Animal Biosafety Level Criteria for Vivarium Research Facilities” in the Biosafety in Microbiological and Biomedical Laboratories document cited above as well as Chapter 6. Laboratory Animal Facilities from the World Health Organization (WHO) Laboratory Biosafety Manual – Third Edition.

5. Inhalation of infectious aerosols.

NOTE: Inhalation of aerosols, including fungus spores, micro particulates, viruses, or bacteria, can be caused by improper fume hood use, unsafe centrifuge handling procedures, opening closed test tubes at close range without proper PPE (personal protective equipment), or mistakes in handling vacuum pumps safely.

Stay Focused and Practice the Steps of Your Experiments Before Handling Potentially Toxic Pathogens and Chemical Agents

Here’s a little thought experiment.

If you were an athlete preparing for a game, wouldn’t you warm up on the field first by stretching and practicing some of your key movements?

What if you were giving an important presentation… wouldn’t you practice your presentation first before ‘going live’?

Why not apply the same approach to your work in the laboratory?

Take the time to practice all the steps of an experiment before you start. Get familiar with all the tools and equipment that you need to conduct the experiment. Take a quiet moment to visualize each of the steps required in your mind. And, most importantly, practice these steps in a ‘dry run’ (using inert chemicals) while wearing the necessary personal protective equipment (PPE), such as gloves, eye, and face protection. Yes, it will be more difficult that way, but that’s the point.

Make sure you are well-rested. If you are unable to get a proper night’s sleep, you will be more accident prone the following day. The same goes for maintaining a reasonable work schedule. If you are working more ten hours a day or you avoid taking adequate breaks, you won’t perform as well as you should.

Understand the Limitations of Fume Hoods and Biosafety Cabinets (BSCs)

Now let’s turn our attention to the kind of lab safety and cross-contamination prevention procedures that need to be in place when working with biosafety cabinets (BSCs).

At a high level, here’s the typical workflow: working samples of chemicals or biospecimens need to be safely and securely taken out of storage and transferred to the work area (typically inside biosafety cabinet, aka fume hood) for an experiment or test procedure. As the work is completed, used test articles must be safely discarded as waste, and any remaining items need to be returned to the secure storage.

What is the right level of protection for your needs? The WHO classifies Biosafety Cabinets (including fume hoods, glove boxes) into increasingly strict categories: Classes I, II, III, and III.

Selection of a biological safety cabinet (BSC), by type of protection needed

Type of Protection |

BSC Selection |

| Personnel protection, microorganisms in Risk Groups 1–3 | Class I, Class II, Class III |

| Personnel protection, microorganisms in Risk Group 4, glove-box laboratory | Class III |

| Personnel protection, microorganisms in Risk Group 4, suit laboratory | Class I, Class II |

| Product protection | Class II, Class III only if laminar flow included* |

| Volatile radionuclide/chemical protection, minute amounts | Class IIB1, Class IIA2 vented to the outside |

| Volatile radionuclide/chemical protection | Class I, Class IIB2, Class III |

(For more information, please see page 52 of the World Health Organization (WHO) Laboratory Biosafety Manual – Third Edition.)

*For a discussion of the difference between ductless versus laminar flow fume hoods, see our report Laminar Flow or Ductless – How to Select the Right Type of Fume Hood.

Lab personnel can easily fall into a trap when working with fume hoods, (particularly the ductless variety that depends on HEPA filters to recirculate air inside the lab).

How so?

It’s easy to overestimate the capability of these units, especially compared to the more powerful laminar flow fume hoods that exhaust directly to the outside.

Keep the following tips in mind, especially when working with ductless fume hood units:

1. Assume Nothing is Sterile

Assume all surfaces are contaminated before commencing work. Even if the unit has a UV disinfection light, this does not guarantee sterility on surfaces, and it is ineffective at sterilizing liquids and solids. Use aseptic cleaning methods.

Be sure to disinfect the work surface as well as anything that is introduced into the fume hood (including gloves, , glassware, Petri dishes, flasks, etc.) before starting and after completing your work. After each use, and especially after spills, wipe down stainless steel surfaces with water or a cleaning solution product recommended by the manufacturer.

2. The Fume Hood is Not a Storage Unit

Keep items that are not used in experiments or test operations in the appropriate secure storage area. Unused items create opportunities for unwanted cross-contamination.

3. Work Clean to Dirty, AKA Left to Right

Use a consistent procedure to handle chemicals or biospecimens. Work in the middle third of the cabinet (about 4 inches away from a front grill vent.) Put clean items on one side (most choose the left-hand side for clean items) and transfer them to the right as they become used/dirty/contaminated) to reduce cross-contamination.

4. Go Slow and Reduce Splatter, Spills, and Aerosols

Keep clean materials at least a foot away from anything that could generate an aerosol vapor. The back of the fume hood is the best location for vortex mixers and tabletop centrifuges that create aerosols (as well as biohazard bags, discarded pipette trays, suction collection flasks). Open caps carefully, placing the caps on toweling. Recap as soon as possible. Hold tubes and bottles at an angle to minimize interaction with airflow (the same goes for Petri dishes: hold lids over dishes to prevent direct airflow.) Pay special attention to handling aspirator bottles and suction flasks; these must be connected to an appropriate overflow flask with disinfectant, and off-gassing vapors need to captured by the inline HEPA filter.

5. Handle Spills Carefully

If there is a spill, use the safety protocol called for. Typically, this will involve immediately placing a towel over the spill to prevent spreading and aerosolization until a chemical decontamination solution can be applied. Typically the towel and spill liquids are treated as waste. After spills, wipe down stainless steel surfaces with water or a cleaner recommended by the manufacturer. If there is an explosion or fire, be prepared to contain a fire igniting in the HEPA filter (some filter types are flammable).

6. Reduce Airflow Interruptions and Maintain Equipment

Ductless fume hoods can be adversely affected by seemingly insignificant changes. For example, maintain the sash opening at a recommended height. Standing too close to the air intakes or moving your arms quickly can interrupt the airflow and filtering. Avoid placing a ductless fume hood near a lab door that is opening and closing, as the resulting air press change in the room can also disrupt the airflow inside the unit. Change the HEPA filters as recommended by the manufacturer. Finally, test the unit on a regular basis to see if it’s operating up to spec.

7. Use Proper Techniques for Handling Chemical and Biological Waste

Practice the proper technique for removing chemical and biological waste. If you are collecting it in a biohazard bag for removal, the proper place to transfer it is within the biosafety cabinet. Do not pull the waste material out of the unit and place it into the bag outside the unit — this defeats the purpose of the BSC!

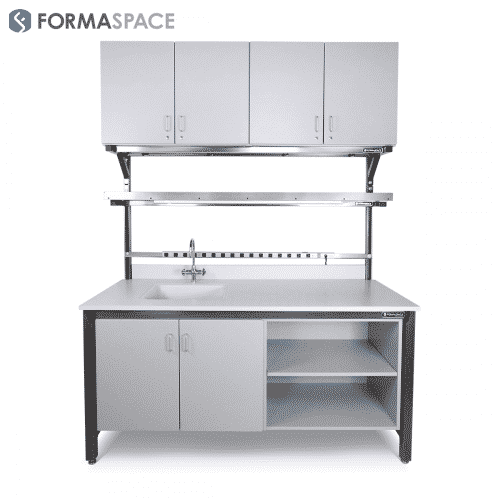

Formaspace Can Help You Work Safer – With a Place for Everything and Everything in its Place

Formaspace is your partner for a safer, more secure laboratory.

You’ll work more efficiently with a clean, well-appointed laboratory that has a place for everything and everything in its place.

In addition to our custom manufactured lab furniture solutions for wet labs and dry labs here at our Austin, Texas factory headquarters, we offer the following products to make your lab safer and more efficient:

· Bio Safety Cabinets and Fume Hoods

· Safety Cabinets for Secure Storage

· Specialty Chemical Storage

· Vivarium Cages

· Radiological Materials Storage

To find out more, contact your Formaspace Design Consultant today.

We can help you make your next laboratory project a complete success.